Editor's note: This story is being highlighted in ASU Now's year in review. To read more top stories from 2017, click here.

Ski boots made expressly for you. White-water oars that cannot break. Featherweight motorcycle helmets inspired by nature. Hot new jobs.

These are a few of the things additive manufacturing — usually called 3-D printing — are going to bring. Introduced about 10 years ago, it’s a process changing materials science, manufacturing and engineering.

Building a robot? Ten years ago, you needed custom-machined parts that were extremely expensive and took a long time to fabricate. Now, the part you need can be created in a day or two, at a fraction of the original cost. Formula One is using additive manufacturing. McLaren is partnering with 3-D company Stratasys Ltd. (two of its machines are in the Polytechnic lab) to print test parts, saving time, cost and, in some cases, performance.

Additive manufacturing is opening up new worlds in engineering. It pulls in biology, chemistry, math and engineering.

“It’s a way of making things that penetrates many disciplines,” said Dhruv Bhate, an associate professor at the Arizona State University’s Polytechnic School, where he conducts research in the design and mechanics of 3-D-printed structures and materials.

“We are at the start of something exciting,” he said. “We are going to see a lot of growth.”

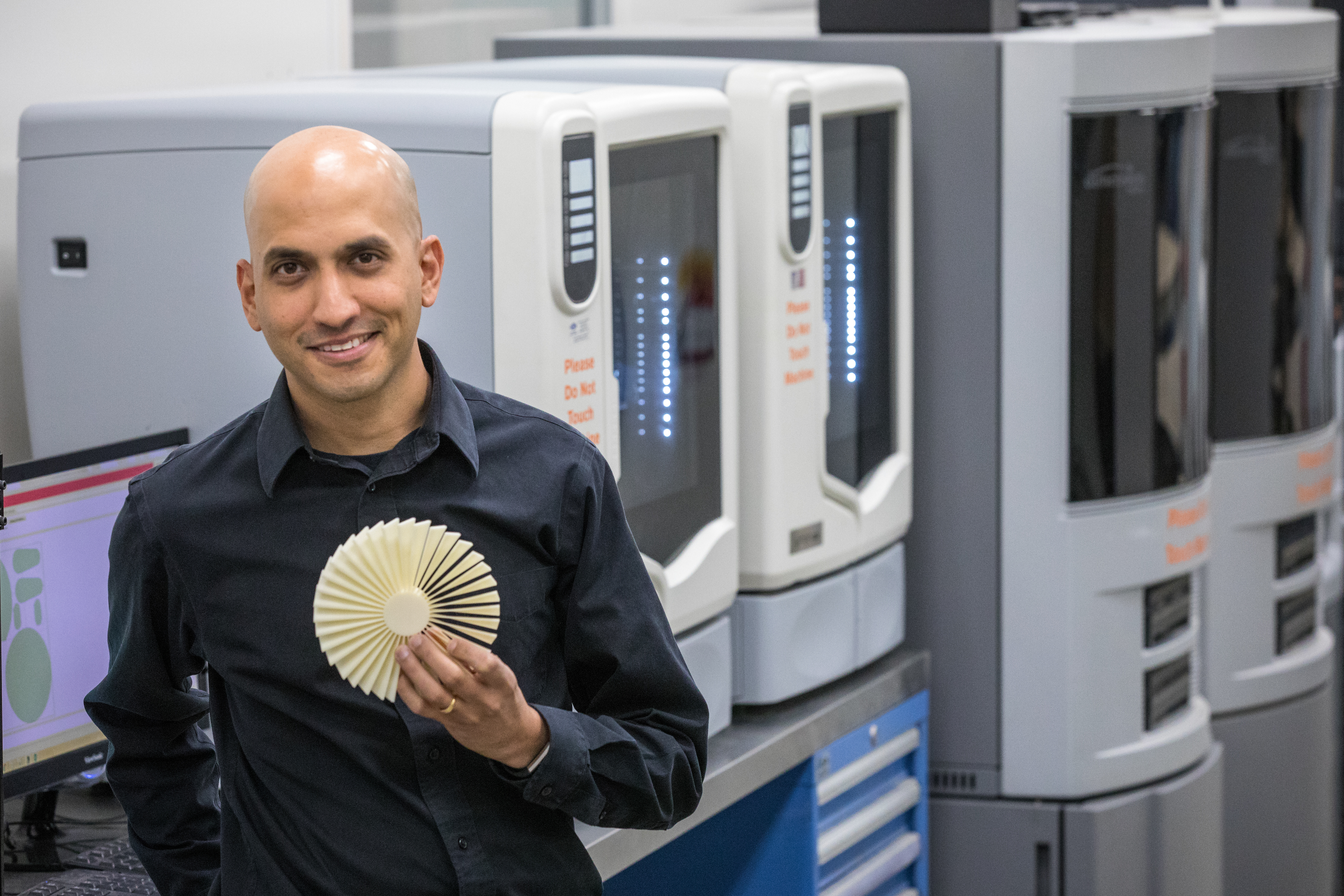

ASU Associate Professor Dhruv Bhate, standing with fused deposition modeling polymer printers, is teaching three additive manufacturing courses on the Polytechnic campus, preparing engineering students for careers that involve industrial or aerospace-grade 3-D printing. The students will be working with both polymer and metal printers. Photo by Charlie Leight/ASU Now

Bhate is one of three faculty recently hired to capitalize on the equipment in the Manufacturing Research and Innovation Hub. The lab is the largest in the Southwest, with more than $2 million worth of cutting-edge plastic, polymer and metal 3-D printing equipment.

“And we’re growing,” Bhate said. “We are in a growth mode to catch up with all the equipment we’ve invested in.”

Four of the five technologiesThe technologies are Fused Deposition Modeling (Stratasys), PolyJet (Stratasys), Laser Powder Bed Fusion (Concept Laser), Selective Laser Sintering (EOS) and Composite 3D Printing (MarkForged). — including the newest arrival, a printer that can use two different materials that just arrived Friday — can be used for functional parts. The fifth technology is PolyJet, which can be used for limited-run tooling.

Bhate teaches three courses in the technology: Additive Manufacturing Processes, Design for Additive Manufacturing and Additive Manufacturing Materials & Structures. Industry is literally screaming for these skills. Orbital ATK and Honeywell requested a class in design for additive manufacturing.

“It is one of the hottest courses in demand right now,” Bhate said.

Honeywell trains 10 engineers every two months in designing with additive manufacturing. The company hired three ASU grads last year and is looking for more, Bhate said.

Aerospace and defense are the top users of the tech, followed by biomedical, according to Bhate. Military body armor is beginning to be 3-D-printed. Airbus has 10,000 3-D-printed parts on every plane it makes.

Here are three things to know about additive manufacturing:

1. It’s all about you

Customization is king. Medical exoskeletons are being 3-D-printed, and the majority of hearing aids are now manufactured the same way. You want Kevlar in this color but not that color? You can do that.

“Somebody did a titanium rib cage recently,” Bhate said. “If you need customization, this technology is giving it to you at a much-reduced cost. ... Customization is such a huge value to 3-D printing.”

2. Nature paves the path

What conditions are right for a 3-D-printed part? Nature dictates a lot of designs. For example, honeycomb structures, which can absorb energy. Traditionally they are hard to manufacture.

“We can truly replicate nature’s designs,” Bhate said. “In 3-D printing we are limited only by how small we can print.”

3. New materials

Before additive manufacturing, people were able to design materials, but not make them.

“You can put any material anywhere,” Bhate said. Kevlar and nylon can be combined, for instance.

“We have been so conditioned to talk about solid materials,” he said. “The boundaries between materials and design is going away.”

Printing layer by layer also produces unique properties that are being studied for the first time.

“We can create structures we couldn’t before and study their properties,” Bhate said. “The big revolution in the last five years is we now make things that can fly.”

Top photo: Examples of 3-D polymer printing, with the honeycomb composed of nylon and carbon fiber and the fan made of ABS plastic. Photo by Charlie Leight/ASU Now

More Science and technology

ASU-led space telescope is ready to fly

The Star Planet Activity Research CubeSat, or SPARCS, a small space telescope that will monitor the flares and sunspot activity of low-mass stars, has now passed its pre-shipment review by NASA.…

ASU at the heart of the state's revitalized microelectronics industry

A stronger local economy, more reliable technology, and a future where our computers and devices do the impossible: that’s the transformation ASU is driving through its microelectronics research…

Breakthrough copper alloy achieves unprecedented high-temperature performance

A team of researchers from Arizona State University, the U.S. Army Research Laboratory, Lehigh University and Louisiana State University has developed a groundbreaking high-temperature copper alloy…