ASU chosen to lead national nanotechnology site

ASU NanoFab is a flexible nano-processing facility that offers state-of-the-art device processing and characterization tools for university research and for external company prototype development. Begun in 1981, this facility, serving the Southwest, was one of 10 nanofabs affiliated with the National Nanotechnology Coordinated Infrastructure Initiative, the predecessor to the National Nanotechnology Coordinated Infrastructure program. It will now be part of the new Nanotechnology Collaborative Infrastructure Southwest.

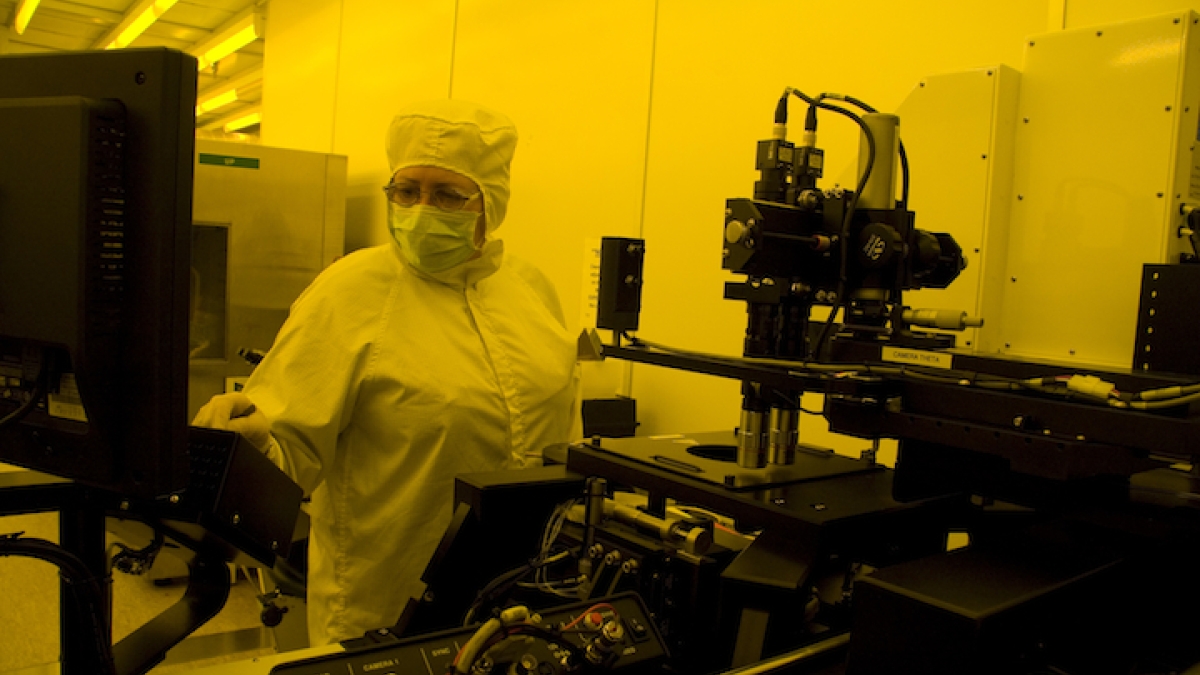

Photo by: Jessica Hochreiter/ASU

Arizona State University has been chosen to lead a new National Science Foundation site that will provide a Southwest regional infrastructure to advance nanoscale science, engineering and technology research.

The National Science Foundation (NSF) will provide a total of $81 million over five years to support 16 user facility sites as part of a new National Nanotechnology Coordinated Infrastructure (NNCI). ASU’s site is funded at $800,000 per year for five years.

The ASU site, like the other hubs, will help researchers from universities, corporations and government to develop electrical, mechanical and biological systems whose components are smaller than the diameter of a human hair. This nanotechnology may be able to create new materials and devices with a vast range of applications: electronics, biomaterials energy production, or consumer goods.

The NNCI sites will provide researchers access to university facilities with leading-edge fabrication and characterization tools, instrumentation, and expertise within all disciplines of nanoscale science, engineering and technology.

Nanotechnology systems are built at the molecular level of less than 100 nanometers. A nanometer is one-billionth of a meter. To put that scale in perspective, the diameter of a human hair is in the range 50,000 to 75,000 nanometers.

The Nanotechnology Collaborative Infrastructure Southwest

The NNCI award has been granted to Trevor Thornton, professor in the School of Electrical, Computer and Energy Engineering, one of the six Ira A. Fulton Schools of Engineering. He will be the principal investigator and director of the new Nanotechnology Collaborative Infrastructure Southwest (NCI-SW).

The goals of the NCI-SW site are to build a Southwest regional infrastructure for nanotechnology discovery and innovation, to address societal needs through education and entrepreneurship and to serve as a model site of the NNCI.

Key partners include the Maricopa County Community College District and Science Foundation Arizona.

Co-principal investigators from ASU include Stuart Bowden, associate research professor in the School of Electrical, Computer and Energy Engineering; Jenefer Husman, associate professor in the Sanford School; and Jameson Wetmore, associate professor in the School for the Future of Innovation in Society, Consortium for Science, Policy & Outcomes, and School of Human Evolution & Social Change.

The NNCI framework builds on the National Nanotechnology Infrastructure Network (NNIN), which enabled major discoveries, innovations and contributions to education and commerce for more than 10 years.

“NSF’s long-standing investments in nanotechnology infrastructure have helped the research community to make great progress by making research facilities available,” said Pramod Khargonekar, the NSF’s assistant director for engineering. “NNCI will serve as a nationwide backbone for nanoscale research, which will lead to continuing innovations and economic and societal benefits.”

According to Thornton, ASU has a well-established nanotechnology infrastructure, with faculty strengths that transcend disciplines.

“This gave us a competitive advantage in being chosen for this award,” he said. “We also successfully directed the NSF predecessor to the NNCI centers, a NNIN site — ASU NanoFab — that wrapped up 6 years of funding at the end of August. The NNCI allows us to expand our offerings and outreach in a big way.”

The NCI-SW site will encompass six collaborative research facilities: the ASU NanoFab, the LeRoy Eyring Center for Solid State Science, the Flexible Electronics and Display Center, the Peptide Array Core Facility, the Solar Power Laboratory, and the User Facility for the Social and Ethical Implications of Nanotechnology.

The NCI-SW site will open the Flexible Electronics and Display Center and the Solar Power Laboratory to the broader research community for the first time.

Societal impacts of nanotechnology

The site will provide particular intellectual and infrastructural strengths in the life sciences, flexible electronics, renewable energy and the societal impact of nanotechnology.

Wetmore will be leading the Social and Ethical Implications component of ASU's NNCI effort.

The Social and Ethical Implications component is made up of two parts: 1) building a social science "user facility" where scholars can come to ASU to learn to use tools to help them collaborate across disciplines and develop a better understanding of the past, present and future social implications of science and technology; and 2) offering programs that train scientists and engineers in how to identify and think about the social aspects and implications of their work.

"The NNCI effort at ASU is exciting because it is a blending of scientists, engineers and social scientists working together not just in name, but in practice,” Wetmore said. "Those involved have a long history of working together and look forward to continuing to develop an engineering workforce that can see the big picture and better work towards social goods."

Building an educated workforce

“What also is outstanding about this program is that it not only focuses on building a nanotech industry, it is equally concerned with creating an educated workforce. Our efforts will span from K-12 all the way to working professionals,” Thornton said.

ASU will collaborate with the Maricopa County Community College District and Science Foundation Arizona to develop STEM (science, technology, engineering and mathematics) materials with a nanotechnology focus for Associate of Science and Associate of Applied Science students in communities throughout metropolitan Phoenix and rural Arizona.

ASU also will provide entrepreneurship training for users who wish to commercialize nanotechnology in order to benefit society. To facilitate the commercialization of research breakthroughs, the NCI-SW will support prototyping facilities and low-volume manufacturing pilot lines for solar cells, flexible electronics and biomolecular arrays.

The Science Outside the Lab summer program at the ASU Washington, D.C., campus will allow users across the NNCI to explore the policy issues associated with nanotechnology.

A web portal hosted and maintained by the Maricopa County Community College District will provide seamless access to all the resources of the NCI-SW.

Through a FY 2016 competition, one of the newly awarded sites will be chosen to coordinate the facilities.

This coordinating office will enhance the sites’ impact as a national nanotechnology infrastructure and establish a web portal to link the individual facilities’ websites to provide a unified entry point to the user community of overall capabilities, tools and instrumentation. The office also will help to coordinate and disseminate best practices for national-level education and outreach programs.

Funding for the NNCI program is provided by all NSF directorates and the Office of International Science and Engineering.

The 16 sites are in 15 states and involve 27 universities, including Stanford, Harvard, Cornell, the University of Texas-Austin, the University of Pennsylvania, North Carolina State University and Georgia Institute of Technology.

Senior personnel for the NCI-SW site include:

Associate Director Neal Woodbury, co-director of the Center for Innovations in Medicine, The Biodesign Institute: Bio-Nanomedicine

Associate Director Thomas Sharp, professor in the School of Earth and Space Exploration: Geological Sciences

Flexible Electronics: Mark Strnad, associate director of the ASU Flexible Electronics & Display Center

Environmental Sciences: Paul Westerhoff, vice provost for academic research programming and professor in the School of Sustainable Engineering and the Built Environment

Nanotechnology Modeling Tools: Dragica Vasileska, professor in the School of Electrical, Computer and Energy Engineering

Entrepreneurial Programs: Audrey Iffert, executive director, ASU Entrepreneurship & Innovation

Web Portal: Michael Lesiecki, Maricopa County Community College District, executive director, Maricopa Advanced Technology Education Center

STEM Outreach: Caroline VanIngen-Dunn, senior manager, Science Foundation Arizona STEM Pathways

More Science and technology

The science behind chronic stress

Stress comes in many shapes and sizes. There’s the everyday stress of preparing for a final exam or being stuck in traffic. And…

ASU planetary scientist to be inducted into the National Academy of Sciences

The National Academy of Sciences is inducting School of Earth and Space Exploration Director Meenakshi Wadhwa into the 2023 class…

Unlocking the potential of AI for homeland security

“Can we do what we're doing now cheaper, more efficiently, more effectively?” Adam Cox, director in the Office of Strategy and…