Modifying the manufacturing mindset

ASU Assistant Professor Feng Ju creates tools for real-time factory floor decisions

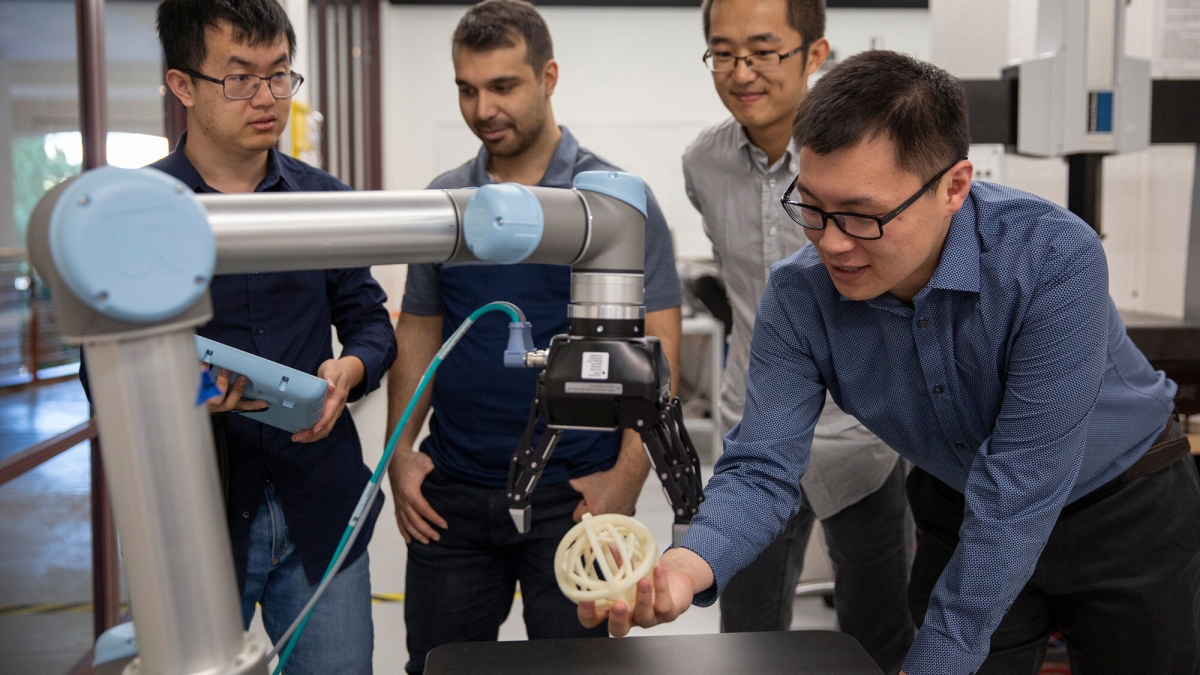

Feng Ju and his team at ASU's Manufacturing and Service Automation Lab are developing tools to advance factory operations and minimize production disruptions. Photo by Connor McKee/ASU

Global manufacturing has entered a new era. Some people call it smart manufacturing or Industry 4.0. Companies apply complex information systems to manage what happens on a factory floor, where almost everything is monitored and processes are streamlined.

“Even so, uncertainties happen all the time,” said Feng Ju, an assistant professor of industrial engineering in the School of Computing, Informatics, and Decision Systems Engineering at Arizona State University. “A production component may fail, or new orders arrive that demand rush delivery. There are many possible sources of disruption at a factory, and any one of them can mess up scheduling or production execution.”

Consequently, Ju’s Manufacturing and Service Automation Lab team at the Ira A. Fulton Schools of Engineering is developing novel computational tools to prevent or minimize the cascading effect of any production disruptions. They do so by applying huge amounts of manufacturing data to support real-time decision-making that enhances production efficiency, quality and safety.

“Our work seeks to support a new generation of manufacturing automation,” Ju explained. “Forty years ago, we saw computer-aided control introduce electronics to the factory floor. That level of automation delivered tools with mostly single purposes. It was very stiff or static.”

Ju points to the example of car manufacturing. Automotive production does rely on complex assembly lines, but the architecture of those same production facilities actually limits the design options for new cars.

“Ideally, the robots and controllers that assemble one type of vehicle should be able to support the assembly of new car designs, too,” Ju said. “However, traditional industrial systems are quite rigid. They are configured and installed to manufacture specific things, and require a lot of engineering effort to reconfigure.”

Ju says that industry now needs the ability to design applications or tools for novel purposes.

“We are moving from high-volume manufacturing with very limited variation in output to low-volume production with constantly varying demands,” he said. “So, we need production facilities that are dynamic. But this kind of change requires a completely different mindset.”

Ju explains why most manufacturing has not innovated to the extent of consumer electronics, for example. When consumers want a new smartphone, they want all the latest features and functions. By contrast, manufacturers traditionally don’t pursue novelty. They acquire industry-standard components for their production system.

“They are thinking about just the final product, and their factory is simply the means of fabricating it,” Ju said. “Moving forward from this model requires thinking of the design and manufacturing process as actually part of what businesses are delivering to customers.”

Enhancing local manufacturing

As a case in point, Ju and his team have been commissioned by Tennessee-based LM Industries Group, or LMI, for a project meant to improve a large-scale additive manufacturing process that fabricates an autonomous, multipassenger shuttle bus called Olli.

“It’s similar to a home 3D printer in that it works through a layering process, but it’s obviously much larger and more complex,” Ju said. “One of the things we are doing is gathering a vast number of thermal images of the print bed to get a sense of real-time changes in layer temperatures during production. We can use this information to create predictive models about the thermodynamics or temperature changes that occur over time in this setting.”

With these models, Ju explains that LMI can identify a production strategy to permit the most efficient, layer-by-layer printing process as they speed up production and increase quality.

“Large-scale additive manufacturing processes are still a fairly new technology,” said Nils Hofmann, director of labs for LMI. “I am certain that this research will uncover additional potential for LMI and ASU to cooperate and create further research opportunities.”

Ju is particularly excited about those future opportunities, since the Olli shuttle bus is just one application of a broader concept.

“The focus of their work is developing flexible, local manufacturing,” he explained. “Consider it a microfactory. The idea is to bring design and production capabilities to individual neighborhoods. People could design and 3D print their desired products right down the street, and then pick them up locally with short lead time. Think of the logistics and warehousing savings, and the reduction in waste. The potential is very exciting.”

Streamlining factory-floor performance at Intel

Ju and his research team also have just started a three-year research project with the Intel Corporation at the company’s campus in nearby Chandler, Arizona. Nital Patel, the principal engineer for assembly test manufacturing systems at Intel, says Ju’s efforts will address a fundamental problem.

“How do you make real-time decisions to keep your manufacturing flow on target given unanticipated disruptions?” Patel said. “Traditional methods look at using simulation coupled with optimization to make these decisions, and these cannot provide answers in real-time. This is of extreme interest as we push the boundaries of using advances in machine learning and artificial intelligence in an industrial decision systems setting.”

Ju explained, “The Intel factory produces many different semiconductor products in a broad range of quantities. And with so many manufacturing processes taking place in the same space, there always are questions to consider about how to make sure that production facilities are being used in the most efficient manner. So, our team is working on several different decision-making tools to better streamline production on their factory floor.”

These projects with LMI and Intel demonstrate the commercial value of the research that Ju and his team are conducting at the Fulton Schools. But recognition of Ju’s innovative work extends beyond these projects.

The National Science Foundation awarded Ju a new $400,000 grant this spring to support research enabling more proactive control of industrial production systems. Also, Ju has been recognized as a 2020 Outstanding Young Manufacturing Engineer by the Society of Manufacturing Engineers. This SME award honors just 15 people under the age of 36 for exceptional accomplishments and contributions to the manufacturing industry.

Alongside such significant professional acknowledgment, Ju remains devoted to advancing new talent within his team at ASU. He doesn’t recognize a boundary separating research and teaching. They happen simultaneously, in real-time.

“It’s very important for my work with students to stay at the front-end of the technology used around the manufacturing world,” Ju said. “We all are fascinated by the opportunities that we have to make a real difference to industry.”

More Science and technology

Celebrating 34 years of space discovery with NASA

This year, NASA's Hubble Space Telescope (HST) is celebrating its 34th anniversary of the world's first space-based optical…

Making magic happen: Engineering and designing theme parks

The themed entertainment industry is widespread and diverse, encompassing everything from theme parks to aquariums, zoos, water…

AI-equipped feeders allow ASU Online students to study bird behavior remotely

ASU Online students are participating in a research opportunity that's for the birds — literally. Online Bird Buddies is a…