Growing up: Welcome to vertical farming

Closed system processes food waste and produces organic produce in record time

Editor’s note: This story is being highlighted in ASU Now’s year in review. Read more top stories from 2020.

A new word will have to be coined to describe Zhihao Chen. Is he a farmer if there’s no farm?

Chen, a chemistry instructor at Arizona State University, has created a new system for growing food. Forget farm to table. Chen has skipped the farm entirely.

In a time when grocery stores are struggling to keep shelves full, Chen’s vertical farm could sit in the corner of a market parking lot, sending lettuce grown from a completely organic closed system to the shelves in as little as three weeks.

The system, which Chen describes as "cleantech," is contained within two standard shipping containers. One 160 square foot space contains a system for breaking down food waste — anything from potato peels to rotten carrots to egg shells — and transforming it into fertilizer and methane gas. It’s capable of processing 2,000 pounds of food waste per day – the amount an average grocery store tosses out daily.

The second container hosts shelves of produce grown in a carefully-controlled environment.

Zhihao Chen, inside the digester container, talks about the vertical farming system he and his colleagues have developed at the Environmental and Resource Management lab, a part of Arizona Center for Algae Technology and Innovation (AzCATI) on the Polytechnic campus. Photo by Charlie Leight/ASU Now

The 320-square-foot space can produce 1,200 heads of lettuce per month — the equivalent of two acres of farmland production. Traditionally, it takes lettuce 30 days to grow to maturity. Chen’s system produces a mature head in three weeks. It also doesn’t depend on climate. And the system uses 95% less water than traditional agriculture.

This could work on an island, in space, at sea — anywhere.

Chen came up with the idea two years ago. An instructor in the College of Integrative Sciences and Arts on ASU’s Polytechnic campus, he assembled a team to work on the project and created a startup called Homer Farms.

He takes food waste from the campus and grows lettuce, which goes back to ASU Dining Services.

“We want to achieve zero waste at ASU,” Chen said. He plans to expand operations to the other campuses. He is also in talks with grocery chains Fry’s and Kroger right now. Fry’s is interested in putting the system in their parking lots to use their food waste.

“The customer can actually see what’s going on,” he said. No pesticides, no chemicals or artificial fertilizers are used. It’s completely organic.

And, he adds, “You pretty much don’t emit any greenhouse gas emissions.”

A lattice of roots float in the fertilizer brine in the racks for the week-old butterhead lettuce. Photo by Charlie Leight/ASU Now

The process is called anaerobic digestion. Certain bacteria under a certain temperature with the proper pH will break down the carbon chain in food waste and feed the carbon into the biogas. (Biogas is a mixture of CO2 and methane.) You can combust the methane for energy to run the unit and heat it to keep growing conditions optimal.

“We process the waste, it becomes liquid fertilizer and biogas,” said faculty sponsor and Assistant Professor Taylor Weiss. “Some of the liquid fertilizer is used in algae production and some is used in the vertical farm to feed the lettuce. When the lettuce is mature, we send it to ASU Dining Services to close the loop.”

It saves long-distance transportation. How about using this in a major metropolitan area like New York or San Francisco?

“We’re able to produce on-site, so the lettuce doesn’t have to be transported from Arizona to New York,” said Chad Geelhood, assistant director of Environmental and Resource Management. “We cut down energy costs, we cut down greenhouse gas emissions, and we make the city more resilient.”

Right now, with the supply chain overwhelmed, “if you have something like that on-site, the city can self-sustain,” Geelhood said. “You don’t have to worry about waste and the food will be supplied on time."

Arizona ranks second, following California, in production of lettuce. Lettuce production in Arizona includes head, leaf and romaine lettuces and is the state's leading cash crop, averaging more than $300 million in value.

“If you air condition the container, it can be year-round in a New York environment,” Geelhood said. “Here we don’t have to add as much heat because we’re in the desert.”

The system can grow any type of vegetables.

Instructional professional Zhihao Chen (left) talks with assistant director of Environmental and Resource Management, Chad Geelhood, inside the growing room with racks of week-old butterhead lettuce. Photo by Charlie Leight/ASU Now

“Lettuce and leafy greens are a good target because they’re high-bulk and it costs a lot to transport them relatively, but also growing them in a closed space makes them more nutritious as well,” Weiss said.

The fertilizer is super-concentrated and has to be diluted. Inside the grow container, temperature, humidity, light intensity and plant temperature are all intensely monitored.

“In that way we can predict the quality we need,” said Yujin Park, an assistant professor in the College of Integrative Sciences and Arts who researches what types of light wavelengths are best for growing. Conditions can be optimized for different crops.

Homer Farms is currently under incubation at University of Arizona Center for Innovation.

Top photo: Assistant Professor Yujin Park checks the week-old butterhead lettuce plants at Environmental and Resource Management (ERM), a part of Arizona Center for Algae Technology and Innovation (AzCATI) on the Polytechnic campus on March 26, 2020. The plants will be ready for harvest at three weeks. With the goal of creating a circular economy, the lab takes food waste from the university's food services and turns it into a fertilizer by way of a digester. The fertilizer is diluted and used as a hydroponic medium to grow lettuce, which is then returned to the food services. Photo by Charlie Leight/ASU Now

More Science and technology

ASU author puts the fun in preparing for the apocalypse

The idea of an apocalypse was once only the stuff of science fiction — like in “Dawn of the Dead” or “I Am Legend.” However these days, amid escalating global conflicts and the prospect of a nuclear…

Meet student researchers solving real-world challenges

Developing sustainable solar energy solutions, deploying fungi to support soils affected by wildfire, making space education more accessible and using machine learning for semiconductor material…

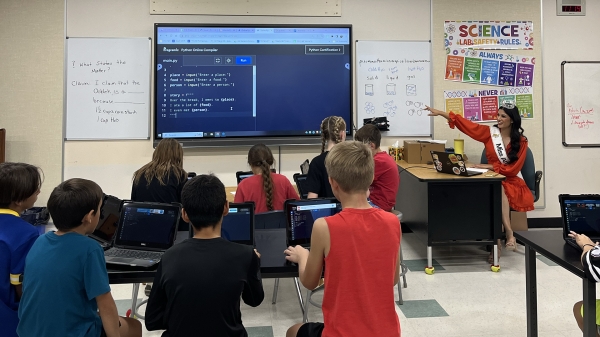

Miss Arizona, computer science major wants to inspire children to combine code and creativity

Editor’s note: This story is part of a series of profiles of notable spring 2024 graduates. “It’s bittersweet.” That’s how Tiffany Ticlo describes reaching this milestone. In May, she will graduate…