The sounds of science: A quiet home for a powerful laser

Biodesign Institute Building C nears completion in February 2018. Its distinctive copper skin shields the building, helping to conserve energy. The structure’s metallic wrap is one sustainable component that helped it attain a LEED platinum certification from the U.S. Green Building Council, the fifth ASU building to earn the designation. Photo by Charlie Leight/ASU Now

Descending into the basement of Biodesign Institute Building C, a stillness settles around you. The sounds of skateboards clacking across sidewalks, students hurrying to class, even the chime of the nearby light rail and rush of traffic fade the deeper you go into the copper-plated, five-story building.

“You can feel it. You can just feel how quiet your feet are,” said Mark Holl. “Theoretically, this is one of the quietest, most vibration-free rooms in the entire Valley.”

Holl is a key figure behind the engineered stillness of Biodesign C. He’s supervising the assembly of a prototype femtosecond X-ray source, the first phase of Arizona State University’s compact X-ray free electron laser. The CXFEL is a specialized instrument that will enable researchers to peer into molecular processes with incredible clarity. Upon completion, it’s expected to be the first of its kind in the world.

The five existing X-ray free electron lasers boast miles-long footprints and price tags in the billions. ASU’s CXFEL is designed to be compact in both size and cost, while delivering most of the same functions as its larger peers.

The CXFEL will use a linear particle accelerator to propel electron bunches to nearly the speed of light through a series of powerful magnets. These magnets will focus and direct the electrons into a beam that collides with concentrated infrared laser pulses to produce brilliant X-rays.

These super fast, super bright X-ray pulses will allow researchers to string together snapshots of molecular processes, effectively creating movies of molecules in action. This is expected to accelerate research in fields from medical imaging and molecular biology to materials science and even art history.

Encased in concrete and sheathed in lead

The specialized capabilities of the CXFEL require a specialized environment. To ensure accuracy and performance, the instrument’s home — the Beus Compact X-ray Free Electron Laser Laboratory — allows for precise control of many factors, including vibration, temperature and humidity, dust and electromagnetic interference.

The Beus CXFEL Laboratory is an oasis of quiet, despite being located within spitting distance of a Valley Metro Light Rail station and the busy intersection of Rural Road and University Drive.

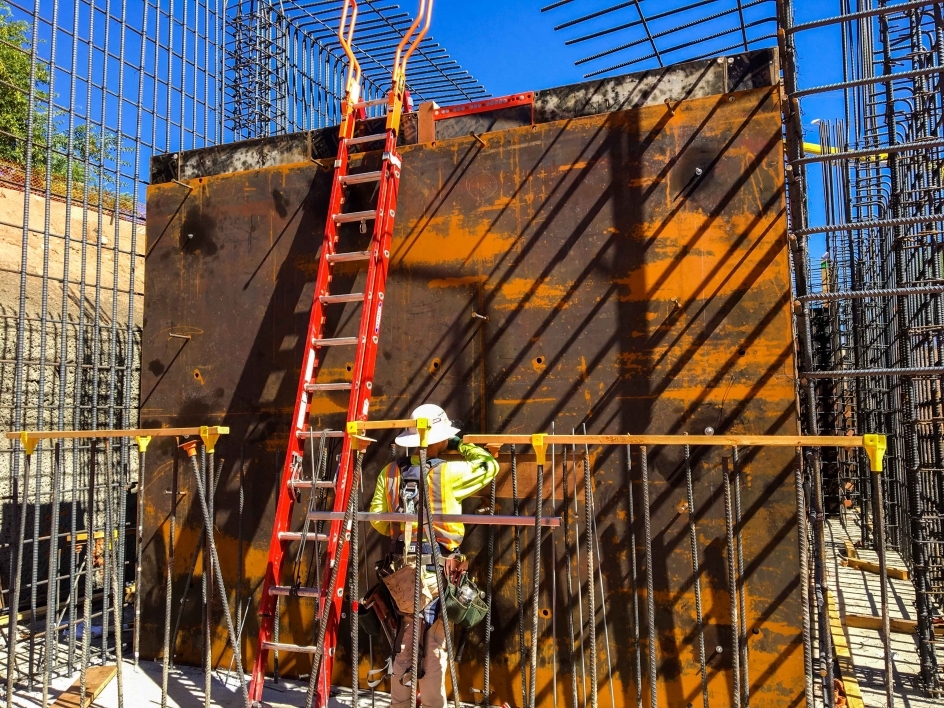

To mitigate the vibrations from passing trains and cars, the most sensitive components of the CXFEL rest on an enormous concrete slab, ranging from four to six feet deep. They are also isolated from other CXFEL equipment support rooms. Within this purpose-built facility, the instrument is being assembled under the direction of Holl, deputy director of the CXFEL project.

Approximately 1,200 cubic yards of concrete make up the slab alone — enough to fill about 5,500 standard bathtubs. It took about 120 trucks around six hours to pour the slab, according to Bryan Kuster, vice president of operations for McCarthy Building Companies Southwest Region, the company that constructed Biodesign C.

“For safety purposes, we wanted to do it at night when traffic was low,” said Kuster, who served as project director on the building. “We had a truck coming in every five to six minutes on this really tight job site. We actually had someone sitting on our tower crane looking out down Rural Road to alert the team on the ground when another truck was coming in. It was quite a coordinated effort.”

The accelerator vault is also surrounded by 4-foot-thick concrete walls. The front wall, in the direction of the accelerated electrons, also includes four inches of lead and eight inches of steel to fully contain accelerator-generated radiation. The vault is capped by a 4-foot concrete lid and sealed by a 2-foot-thick, 36,000-pound lead-shielded door.

Minimizing magnetism

In addition to containing the energy from the laser, the construction team had to take special care to avoid interference from the magnetic fields in the surrounding building materials.

“Usually when you build concrete walls, you use structural steel rebar to increase the strength of those walls,” Kuster said. “The challenge here was that rebar gives off magnetism that would have affected the electron beam of CXFEL and therefore its overall operation.”

Options to solve this challenge ranged from using stainless steel rebar to fiberglass to epoxy-coated rebar, all of which proved prohibitively expensive. Ultimately, Kuster bought a gauss meter to test individual pieces of rebar for magnetism, selecting pieces that were suitable for the vault.

The accelerator vault and supporting laser laboratory, microwave radio frequency transmitter room and experimental hutch also have dedicated mechanical systems to deliver the required tolerances for temperature and humidity. Even the basement’s water, heating, ventilation and air-conditioning systems and air handlers are separate from the building’s upper floors.

A unifying force

While McCarthy handled the actual construction of the building, BWS Architects and ZGF Architects designed Biodesign C.

“We had some lofty goals, but I think the architecture team found a way to have a very appealing building while remaining very sustainable,” said Monica Perrin, a senior project manager with ASU’s Capital Programs Management Group.

The building recently received a LEED platinum certification from the U.S. Green Building Council, the fifth ASU building to earn the designation.

Perrin was involved with Biodesign C from the initial conversations all the way to the official opening of the building. A facet of ASU Facilities Development and Management, CPMG oversees design, renovation and construction of facilities and infrastructure as well as managing contractors and consultants. As soon as Perrin and her team learned about the CXFEL in the design phase of the building, they began to make adjustments to accommodate the instrument.

“We build science labs — as different as they all are — and this one is something completely out of the ordinary,” she said. “Obviously, it was exciting for the entire team to be part of the design and construction of this special lab for these scientists.”

Her team brought in Associate Professor Bill Graves — the physicist who conceived of the CXFEL — and Holl as early as possible to understand the requirements of the laboratory.

“Fortunately for us, Dr. Holl has a background in engineering and I would venture to say he was part of the design team,” Perrin added. “Building this lab without his support and knowledge would have been a real challenge, if not impossible.”

A significant challenge was balancing the three major components of the building: program, aesthetics and maintenance. Program dictates the purpose the building will serve — in Biodesign C’s case, primarily a laboratory. Aesthetics pertains to the actual appearance of the building, and maintenance refers to the cost and considerations of a structure’s upkeep over time. Juggling program with the building’s appearance and maintenance proved difficult, as such a large amount of resources were dedicated to the basement and the Beus CXFEL Laboratory.

“The instrument in the basement was a unifying force because everybody understood how unique it was,” said Tamara Deuser, associate vice president and chief operating officer of ASU Knowledge Enterprise. Deuser represented Knowledge Enterprise throughout the project.

Both McCarthy and ZGF brought in specialists to work with ASU on the requirements of a building housing a miniaturized high-fidelity X-ray source in its basement. Perrin brought in ASU Environmental Health and Safety to determine the type of testing and certification the Beus CXFEL Laboratory will require.

“That was incredibly challenging because the only model we have are these two-mile-long lasers that are not the same,” Deuser said. “This has never been done before.”

Due to the complexity of the project and the special construction considerations of the CXFEL, McCarthy established an entire quality program dedicated to the lab. The team worked with Holl and Graves, as well as ASU Regents Professor Petra Fromme, to construct a suitable environment for the CXFEL.

“Everything we're doing here is specialized,” Holl said. This includes a massive Faraday cage to house the laser’s microwave radio-frequency equipment.

“In most cases, people build Faraday cages to keep the world and its electromagnetic interference out. Here we do it to keep ours in,” Holl said.

The equipment, which is powerful enough for use in radar systems, is incredibly “noisy,” electromagnetically speaking. It could disrupt the sensitive signals and equipment in nearby rooms, as well corrupt data lines in Biodesign C’s laboratories. McCarthy brought in a subcontractor to aid in the Faraday cage’s construction and ran through an extensive commissioning process to ensure no energy from the equipment leaked out.

New territory on familiar ground

Though Biodesign C opened more than a year ago, the jewel of the building — the CXFEL — is still taking shape. Currently, Holl’s team of engineers and scientists is assembling the first phase of the project, the compact X-ray light source.

Despite his 12 years at ASU constructing a range of different instruments, Holl says the CXFEL is unlike anything he’s done before.

“Overall, this is certainly the most complex, most involved project that I've taken on in my career, because it extends in breadth from building architectural conceptual design to detailed design of precision mirror micromanipulators,” said Holl, who’s poured well over 10,000 hours into the design and assembly of the building, instrument and its supporting infrastructure.

“We didn't get from IKEA a set of instructions and a kit to say how to do this,” he added. “We're inventing the instructions as we translate the concepts, the physics and the modeling into engineering specifications, designs, and then through fabrication, procurement and assembly.”

The very novelty of the instrument was a source of excitement for all involved, however.

“How often do you get to build something of this caliber and design, right? I just remember an overall feeling of, ‘Wow, we're doing something special here,’” Perrin said.

Kuster noted that McCarthy drew from experience building other laboratories, hospitals and health care facilities, but they don’t often find themselves constructing a building to house a never-before-seen instrument.

“It's never been done before!” he said. “Not only have the researchers never built a laser like this before, but we were figuring out how to deliver the facility that's going to house that laser.”

An ASU alumnus, Kuster never thought he’d find himself in the position of contributing to such a novel project, but relished the opportunity.

“One of the things that I had always wanted to do was build something spectacular on the ASU campus and I was ecstatic when we were selected for the job,” he said. “A lot of folks have a dream of going back to their alma mater and building something special there, but there are not many times you get to build a facility that is going to make a difference in the world, and is also the first of its kind.”

Written by Pete Zrioka

More Science and technology

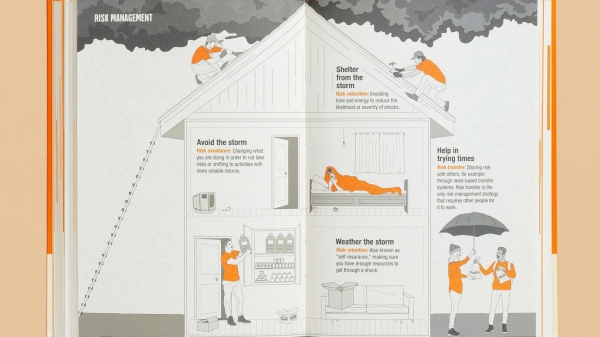

ASU author puts the fun in preparing for the apocalypse

The idea of an apocalypse was once only the stuff of science fiction — like in “Dawn of the Dead” or “I Am Legend.” However…

Meet student researchers solving real-world challenges

Developing sustainable solar energy solutions, deploying fungi to support soils affected by wildfire, making space education more…

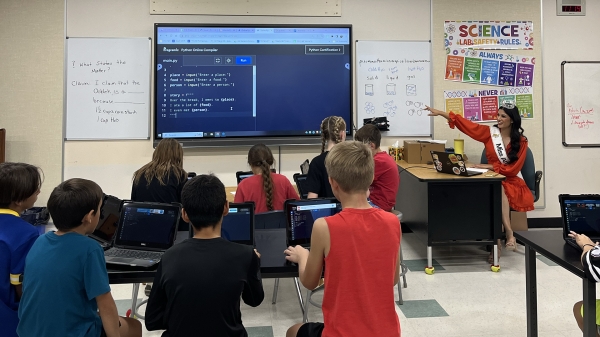

Miss Arizona, computer science major wants to inspire children to combine code and creativity

Editor’s note: This story is part of a series of profiles of notable spring 2024 graduates. “It’s bittersweet.” That’s how…