The U.S.-Pakistan Centers for Advanced Studies in Energy (USPCAS-E) project launched in 2015 with a $60 million investment from USAID. It was conceived as a five-year partnership between Arizona State University and two leading Pakistani universities — the National University of Sciences and Technology (NUST) and the University of Engineering and Technology Peshawar (UET Peshawar) — together with supporting partner Oregon State University.

Its charge: develop innovative solutions to Pakistan’s energy challenges through a host of initiatives, from modernizing curriculum and infrastructure within NUST and UET Peshawar to facilitating enhanced learning opportunities for faculty and students through academic exchange programs and joint research projects at ASU and OSU.

Additionally, the project sought to foster partnerships between public and private energy stakeholders in Pakistan, thereby ensuring that the initiative would continue to yield results long after its conclusion in 2019.

A story of connections made

The origins of USPCAS-E stretch back to 2010, when representatives from Pakistan’s Higher Education Commission and USAID first began discussing an energy-related education initiative. Over the next four years, risk assessments were done, RFPs were developed, competitive bids were submitted, winners were chosen, and in 2014, the project launched.

In the intervening five years, partnership members have worked tirelessly to establish two centers of learning capable of making significant, long-term contributions to solving Pakistan’s energy challenges. The results of their efforts are nothing short of astounding.

“In just five years, we have established two credible institutions for energy education in Pakistan, with healthy intakes of students, competent faculty and state-of-the-art facilities,” said NUST Deputy Director Ahmad Saeed. “I believe this is particularly impressive because when we started, NUST’s Center of Energy Systems had no building, only rudimentary labs, and a single master’s program in energy systems engineering, and UET Peshawar had nothing.”

Curriculum development was a major component in the undertaking, Saeed said. A needs assessment was done, and courses were created based on the country’s greatest challenges. Faculty from ASU, NUST and UET Peshawar worked jointly to develop the curriculum, with help from OSU Professors Kendra Sharp and Brian Fronk.

ASU faculty also engaged Pakistani energy stakeholders in the process, and faculty from NUST and UET Peshawar were encouraged to query stakeholders as to how the centers could help in solving real-world problems through applied research projects. “These relationships will help the centers continue to move forward after the project ends,” Saeed said. “By working closely with stakeholders, we can identify research projects, cultivate funding sources, and help our graduates find work.”

A series of goals surpassed

Initial results show the project is working just as the partners had hoped.

“It rarely happens that projects such as these achieve their stated goals, but with the USPCAS-E program, NUST and ASU not only achieved their goals, they overshot them,” Saeed said. For example, he says, NUST was charged with awarding 250 merit-based scholarships but gave more than 300. Its center was challenged to start three new programs but launched seven, and when asked to identify 100 students to participate in the exchange program, NUST tapped 110.

ASU’s dedication to the project was equally important, Saeed said. “From the outset, ASU faculty and administration were committed not just to do something, but to do something great.”

The support provided by USAID throughout the five-year project was crucial as well, Saeed said. “Anytime there was a problem, USAID staff was there to help. Their oversight and support throughout the project were exceptional.”

Sayfe Kiaei, USPCAS-E project director at ASU, is also pleased. “Within five years, we have developed 14 new master's and PhD degree programs and more than 150 new courses; graduated more than 300 master’s students, nearly one-third of whom were females or underrepresented minorities; and enrolled more than 1,000 students in degree programs at NUST and UET Peshawar,” he said.

These impressive gains were realized in part due to the technical expertise and research capabilities available through ASU’s multidisciplinary energy centers, said Kiaei. ASU faculty also brought their expertise to bear on issues of energy policy and governance.

“Here at ASU, we’re working to transform energy systems by tackling issues from research and regulation to strategy, entrepreneurship, policy and pedagogy, and through the USPCAS-E project, we were able to share that knowledge with our partners in Pakistan.”

An experience of learning shared

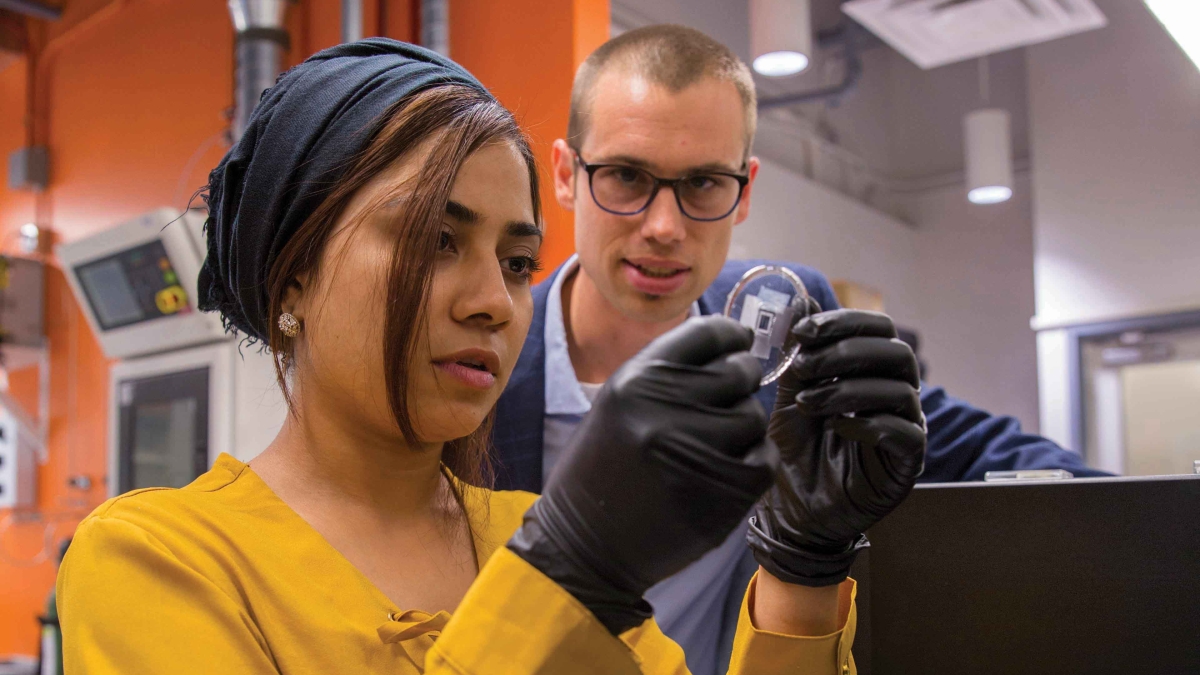

ASU Associate Professor Zachary Holman was among those who traveled to Pakistan to lead technical training workshops for faculty, staff and stakeholders. He also hosted exchange scholars in his ASU laboratory.

“I was perhaps most surprised by what my Pakistani exchange students found valuable,” Holman said. “It turns out that the hands-on learning component of working in my lab was critical. To be trusted to use extremely expensive equipment on their own, anytime, was incredibly important to the students, and quite different from their experiences in Pakistan."

Empowering the exchange students with intellectual responsibility was another important step, says Holman. In Pakistan, faculty typically remain more distant from students, dispensing wisdom in a one-way relationship, whereas at ASU, faculty and graduate students interacted with the Pakistani exchange students on a first-name basis and expected them to carry their weight on research projects.

“This level of responsibility was new to them and transformative,” Holman said. “Many left with a new attitude: ‘I can do more than I realized, I just need to be trusted and trust myself.’”

Holman also benefited. The professor gained a new doctoral student — after spending a semester in Holman’s lab, Warda Mushtaq elected to return to ASU to pursue her PhD — and his graduate students and postdocs learned more about themselves.

Warda Mushtaq, USPCAS-E exchange scholar and graduate, is now pursuing a PhD at ASU. Photo by Jessica Hochreiter/ASU

“Several members of my lab mentored our exchange students,” he explained. “Some realized they liked teaching, and others discovered it wasn’t their calling. In both cases, they got a better sense of what they’d like to do in their own careers.”

In short, says Holman, the USPCAS-E project was tremendously valuable to everyone involved. “The research relationships that have been formed will persist long after the project is completed,” he said.

A path forward set

“Research is an ongoing effort that links faculty on both ends of the project,” agreed ASU Professor A.M. Kannan, the research component lead and joint research project principal investigator for the initiative. “Sustainability was a major component of this initiative, so we wanted to ensure that we helped NUST and UET Peshawar faculty master the elements of a successful research program.”

For example, says Kannan, Pakistani faculty wanted training in writing a successful research proposal, so ASU held a proposal writing workshop at NUST. ASU also assessed the universities’ research facilities and made recommendations as to the equipment they should procure. And when exchange students came to work in ASU’s labs, faculty members guided them in proper protocols.

“Our students returned with a sense of confidence and a determination to pursue research more aggressively,” Saeed said.

Pakistani exchange scholar Maria Kanwal puts it more bluntly.

“Spending a semester working in the lab of Professor Zachary Holman was life-changing,” she said. “Working with PhD students and postdocs, I learned how research is conducted in a focused environment, helping me become immersed in my work and improving my ability to approach problems in the lab.”

Now back in Pakistan, Kanwal has permanently altered her plans for the future. She has applied for a scholarship and hopes to begin working on her PhD in a U.S. or European graduate program in September 2020. After completing her doctorate, she plans to return to Pakistan and implement what she has learned.

“My degree won’t just be hanging on my wall,” she said.

Graduate student Mushtaq is similarly enthusiastic. She, too, spent a semester in the states as an exchange scholar in Professor Holman’s lab and has now returned to complete her PhD under his tutelage.

“The main challenge I faced during my research work in Pakistan was limited availability of resources — I wasn’t even sure I wanted to participate in the exchange program when the opportunity arose — but my experience with the faculty, equipment and lab facilities at ASU helped me to focus and determine next steps,” Mushtaq said.

After completing her doctorate, she plans to return to Pakistan and pursue a faculty position at NUST.

Faculty members in Pakistan have also benefited from the exchange program. Affaq Qamar, an assistant professor under an electrical energy system engineering program at UET Peshawar, spent four and a half months at ASU, conducting a joint research project with ASU Professor Bertan Bakkaloglu, participating in the Technology Entrepreneurship Lab under the guidance of Start-Up Program Faculty Associate Kenneth Mulligan, and bolstering his teaching skills through completion of the Advancing Instructional Methods (AIM) certification program with Professor Peter Rillero.

“I learned how to organize lectures, introduce concepts and more actively engage my students in the learning process.”

Back in Pakistan, Qamar says, the change in his classroom was profound.

“Before the AIM training, my interactions with students were pretty basic — I asked questions and they answered. But when I began applying the concepts I learned while at ASU, the whole dynamic changed. My students began to participate actively in the learning process, challenging me and gaining confidence in their knowledge.”

And that confidence has translated into higher postgraduate job placements, Qamar said. “Electrical engineers here are going through tough times in terms of job placement, but my students are getting jobs because they know their field and believe in their abilities.”

A future of endless possibilities

“Through the USPCAS-E program, we’ve given individual students in Pakistan opportunities that they never would have had,” Kiaei said. “We’ve established two centers that deliver state-of-the-art, 21st-century energy education, and as graduates begin their careers, this knowledge will propagate throughout the country.”

Initiatives within the program have also helped to lay the groundwork to develop hybrid energy sources in Pakistan’s rural areas and decrease the number of regularly scheduled power outages, work that Kiaei is confident will continue.

Faculty and administrators at ASU have profited from the experience as well, says Kiaei. “The USPCAS-E project gave us the opportunity to execute an international project and we learned a lot. Our success underscores the fact that ASU’s outreach is global.”

Clark Miller, a professor in the School for the Future of Innovation in Society and director of ASU’s Center for Energy and Society, served as the USPCAS-E program’s joint research project principal investigator and witnessed firsthand the positive impact of the project on all parties. Miller hosted three Pakistani faculty and 30 students in his lab over the course of the five years, held video conferences with Pakistani faculty every other week throughout the project, and travelled to Pakistan twice.

The program has allowed structures to be put in place in Pakistan that can drive long-term change in the country’s energy systems, Miller observes. “NUST and UET Peshawar are institutions with durability. Now they have an integrated perspective on energy, together with the knowledge and tools, that will allow them to advance the energy goals of the nation.”

Written by Lori Ferguson

Top photo: Professor Zachary Holman works in the lab with Maria Kanwal as part of the USPCAS-E program. Photo by Jessica Hochreiter

More Science and technology

ASU receives 3 awards for research critical to national security

Three researchers in the Ira A. Fulton Schools of Engineering at Arizona State University have received grant awards under the Defense Established Program to Stimulate Competitive Research, or…

Celebrating 34 years of space discovery with NASA

This year, NASA's Hubble Space Telescope (HST) is celebrating its 34th anniversary of the world's first space-based optical telescope, which paved the scientific pathway for NASA's James Webb Space…

Making magic happen: Engineering and designing theme parks

The themed entertainment industry is widespread and diverse, encompassing everything from theme parks to aquariums, zoos, water parks, museums and more. The Theme Park Engineering and Design…