ASU professor named to Fast Company’s 'Most Creative People in Business 2019'

Hao Yan is the ASU Milton D. Glick Distinguished Professor and director of the Center for Molecular Design and Biomimetics and professor in the School of Molecular Sciences.

Editor's note: This story is being highlighted in ASU Now's year in review. Read more top stories from 2019.

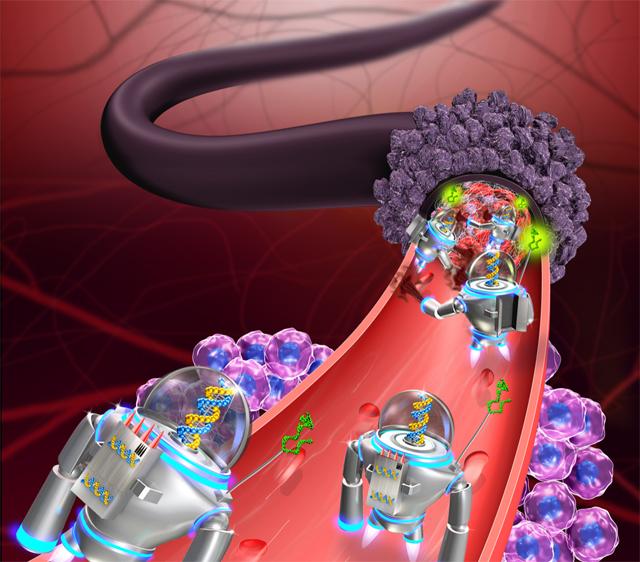

Arizona State University Biodesign Institute researcher Hao Yan has been named to Fast Company’s list of “Most Creative People in Business 2019” for his work using nanobots to fight cancerous tumors by choking off their blood supply.

Fast Company recognized Yan’s work using nanorobots to treat cancer at the molecular level. A pioneer in the field of DNA origami, Yan and his team in the Biodesign Center for Molecular Design and Biomimetics draw their inspiration from nature, seeking to solve complex human problems.

The magazine’s annual list seeks to highlight individuals across a wide range of fields who “have accomplished something over the past year that has moved an entire industry forward in an unprecedented way." Yan is among a highly diverse group of people recognized, including actress Michelle Pfeiffer, late night talk show host Seth Meyers, athletes, activists and artists.

“I’m very honored to be included on this list,” said Yan, the Milton D. Glick Distinguished Professor in the School of Molecular Sciences. “I am a scientist. I don’t think of myself as a businessperson.” Despite his science-first focus, Yan’s entrepreneurial spirit led him to launch Nanobot Biosciences, an early stage startup that is poised to move his technology into commercial use. Yan hopes to begin to be able to treat human cancer patients within the next five years.

Fast Company focused on Yan’s work in building robots that are “one-thousandth the width of a strand of hair — and “constructed from DNA folded into 3D shapes.” The nanorobots are programmed to shrink tumors by finding the source of blood supply to the tumor and stopping that supply. Highly significant in this advance is that it does not affect the healthy cells — a conundrum in the world of cancer care with treatments like chemotherapy and radiation therapy. According to Fast Company, this “unique form of nanostructure technology has shown promise in initial tests, doubling the survival rate of mice with cancer.”

Fast Company focused on Yan’s work in building nanorobots programmed to shrink tumors by finding the source of blood supply to the tumor and stopping that supply.

Yan attributes his ability to think creatively to nature, ASU President Michael Crow and being housed in a highly interdisciplinary research environment at ASU’s Biodesign Institute.

“President Crow is someone I truly admire. He is always thinking outside the box,” said Yan. Yan explains that being at ASU means he is unconstrained by traditional boundaries and has freedom to take risks. Yan believes that perfection can sometimes be the enemy of creativity.

“The world comes with a lot of perfectionism,” said Yan. “While I have a habit to think deep and dig deeper, I can’t be creative if I am always trying to find the perfect answer. Looking around, it is simply not a perfect world, we need to find creative solutions for unmet challenges and be willing to take risks”.

"Professor Yan is an outstanding researcher who is constantly innovating to address grand challenges in health through an interdisciplinary approach,” said Sethuraman Panchanathan, executive vice president, ASU Knowledge Enterprise and chief research and innovation officer. “His work exemplifies the spirit of creativity that has the potential for global impact. He richly deserves this recognition.”

"Can a robot fight cancer? Yes, but it needs to be really, really tiny, which is why Hao Yan and researchers at ASU and China’s National Center for Nanoscience and Technology are building nanobots that are one-thousandth the width of a strand of hair." (Fast Company)

Yan also takes pride in creating an atmosphere where up-and-coming scientists can thrive. “I throw them in the pond and let them swim. I don’t want to produce a technician. I want to produce a creative thinker and a scientist who can come up with their own ideas and solve problems on their own.” Testament to that approach is the fact that Yan’s lab boasts three researchers who have been named “New Innovator” by the National Institutes of Health. He considers identifying promising scientists as one of his most creative acts.

“Creativity and courage are at the crux of good science,” said Joshua LaBaer, Biodesign Institute executive director. “Hao’s work inspires us all. He is representative of the intellectual curiosity that drives our organization – and most certainly, the spirit of innovation that is fostered and encouraged throughout Arizona State University.”

“The environment at Biodesign Institute really provides a space for people to easily reach out to so many different disciplines,” said Yan. He appreciates the ability to keep learning from others. “I didn’t know about tumor biology or cancer immunotherapy before, but now due to my colleagues here, I can merge my knowledge with theirs. I am always learning.”

Asked what he would do if he wasn’t a scientist, he said, “I would be a rock star, playing electric guitar and singing on stage.”

China’s National Center for Nanoscience and Technology is a partner in Yan’s work.

Yan’s honor comes a few years after another ASU luminary, Charles Arntzen, was named to the magazine’s 2015 Most Creative People. Arntzen, a co-founder of the Biodesign Institute, was recognized for his leadership role in developing ZMapp, a therapeutic to fight Ebola, produced in tobacco plants.

Written by Dianne Price

More Science and technology

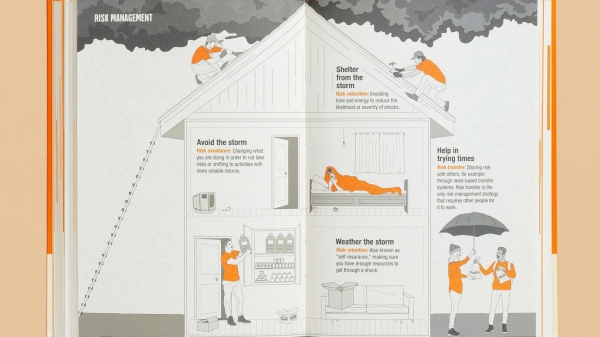

ASU author puts the fun in preparing for the apocalypse

The idea of an apocalypse was once only the stuff of science fiction — like in “Dawn of the Dead” or “I Am Legend.” However…

Meet student researchers solving real-world challenges

Developing sustainable solar energy solutions, deploying fungi to support soils affected by wildfire, making space education more…

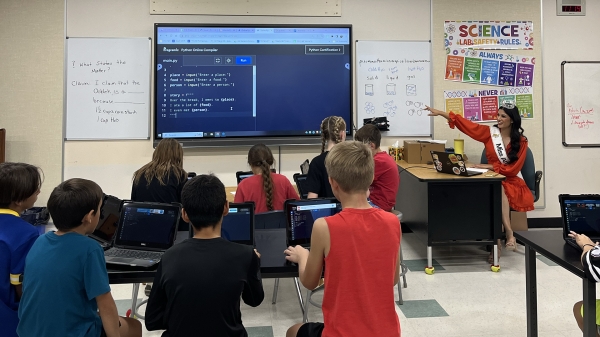

Miss Arizona, computer science major wants to inspire children to combine code and creativity

Editor’s note: This story is part of a series of profiles of notable spring 2024 graduates. “It’s bittersweet.” That’s how…