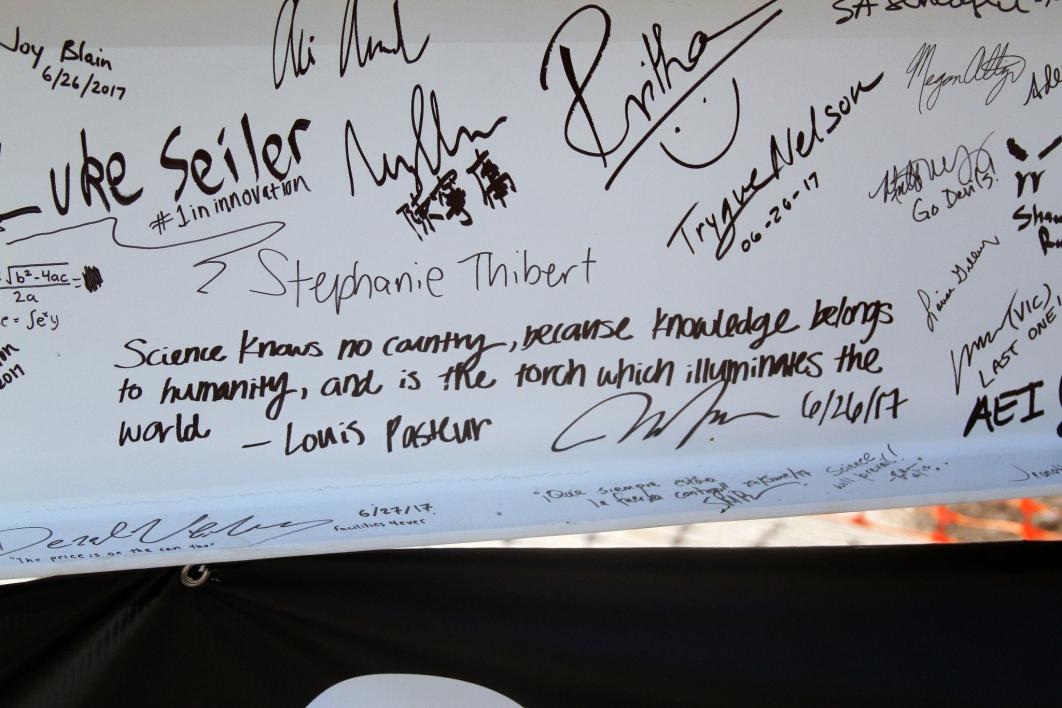

ASU's Biodesign C marks milestone with topping-out celebration

Research building will house a key drug discovery and bioenergy research tool: The world’s first compact free-electron X-ray laser

Arizona State University celebrated a major research building construction milestone Wednesday morning with the topping out of the $120 million Biodesign Institute C Research Building.

The ceremony officially commemorated the completion of the main structural work and gave the community a preview of future benefits when the third building in the ASU Biodesign Institute’s master-planned, 14-acre complex located on the main campus in Tempe, Arizona, is completed in the summer of 2018.

Video by Grace Clark/ASU

Joshua LaBaer, Biodesign’s executive director and a renowned cancer researcher, sees the addition of this new space as concrete evidence of ASU’s significant commitment to leading the field with discoveries that keep people and the planet healthy.

“Powered by intellect, energy and innovation, our researchers believe they can accomplish what others often find impossible,” said LaBaer. “With the addition of Biodesign C, we will soon have nearly 700 scientists of all kinds — biologists, engineers, chemists, physicists, mathematicians, computer technologists — and students working together to find creative and clean solutions for energy, air and water. We will invent new diagnostics and treatments that are accessible and affordable, and in some cases, we expect to be able to halt disease before it even begins.”

After a welcome address from Tamara Deuser, acting chief operating officer for the Biodesign Institute and associate vice president of research operations at ASU's Knowledge Enterprise Development (KED), the final beam was hoisted aloft — a 21-foot-long, quarter-ton metal beam placed by workers for McCarthy Construction, which oversees the construction of the nearly 200,0000-square-foot building. Attached to the beam were an American flag, Biodesign banner and a pine tree, traditional emblems of topping-out ceremonies for steel-constructed buildings.

“Topping out marks a significant milestone in the construction process, signaling the final beam placement of a new structure,” said Justin Kelton, president of McCarthy Building Companies’ Southwest division. “For a research facility of world-class caliber like Biodesign Institute C represents, topping out is even more meaningful because it brings with it significant hope for our future and the promise of new discoveries and innovations.”

Biodesign Institute C will house a key drug discovery and bioenergy research tool — the world’s first compact free-electron X-ray laser — a super X-ray that will peer deep inside proteins to better understand both the action of molecules critical to cancer and other devastating diseases and better understand how plants convert sunlight into renewable energy. Scientists of varying disciplines will be in the lab’s “neighborhoods,” a layout of close proximity that encourages collaboration. The design is modeled after state-of-the-art research complexes like the J. Craig Venter Institute in La Jolla, California, which was also built by McCarthy.

Major research highlights include the following:

A custom-designed vault in the basement will house the world’s first compact X-ray free-electron laser, attracting top-line researchers nationwide. This project miniaturizes existing technology that stretches out about kilometers long and is currently only available in California, Japan and Korea. Scientific “gridlock” is delaying the discovery of new, more effective drugs and clean energy. Once ASU has successfully completed this project, the technology can be made available to research centers throughout the world.

Led by Eric Reiman, the new ASU-Banner Neurodegenerative Disease Research Center is expected to be one of the world’s largest basic science centers for the study of Alzheimer’s and other neurodegenerative diseases. The team is working to develop clinical and research programs with Banner Health.

This new building and its inhabitants will drive ASU’s collaborative spirit of innovation far into the future, building on ASU’s reputation of No. 1 in innovation in the nation. Building C is designed to be a workplace that drives cooperation and collaboration between researchers from different fields — to accelerate our ability to drive new solutions into practice, called use-inspired research. Talented researchers from the Biodesign Institute, College of Liberal Arts and Sciences and Ira A. Fulton Schools of Engineering will eventually house 80 lead researchers and 300 support staff, bringing Biodesign’s total workforce to 700 strong.

The cost of the building is $120 million. It is funded by “green bonds” that allows investors to invest directly in projects identified as promoting environmental sustainability on ASU campuses.

At full capacity, Biodesign C is expected to increase ASU’s annual research expenditures by an estimated $60 million, supporting ASU’s goal of increasing research revenue to $850 million by 2025 and contributing an estimated $750 million to the Phoenix metro area in the coming decade.

Building C is 189,000 square feet, 60,000 of which is flexible lab space (bringing the total size of all three Biodesign buildings to 535,000 square feet).

Additionally, following ASU’s green building standards, Biodesign Institute C has been designed to the highest levels of sustainability and includes an innovative HVAC system to limit its energy and environmental footprint.

The new research facility includes five stories, a mechanical penthouse, plus a basement that connects with the ASU Biodesign Institute B building and will house the X-ray laser facility. The building’s adaptable design will accommodate multiple types of scientific research, including chemistry, biological sciences and engineering research. The building, composed mostly of wet laboratories and offices, also includes high-bay spaces.

The project team, which includes architects Zimmer Gunsul Frasca and BWS Architects in addition to general contractor McCarthy Building Companies, is employing the latest in virtual-reality technology and modeling to successfully execute this project for fast-track completion in spring 2018.

Some of the design and construction solutions implemented to date include:

Building a small exterior mockup on site using building materials to test for any deficiencies before actual construction. This mockup was put through extreme worst-case scenarios of wind, water and smoke tests to ensure energy efficiency.

Creating an interior lab space mockup for researchers to understand the placement of important features like sinks, gas outlets, counter heights, etc.

Developing an extensive pour process for the 19 white concrete columns, ensuring consistent color, sharp edges, smooth surface and precise angles to fulfill the design goal of support while also serving as a building showpiece.

Degaussing (the process of decreasing or eliminating a remnant magnetic field) all rebar in linear accelerator and laser labs, which saved approximately $1 million.

The targeted official opening date of Biodesign C is June 2018.

Top photo by Veronica Gomez

More Science and technology

ASU receives 3 awards for research critical to national security

Three researchers in the Ira A. Fulton Schools of Engineering at Arizona State University have received grant awards under the Defense Established Program to Stimulate Competitive Research, or…

Celebrating 34 years of space discovery with NASA

This year, NASA's Hubble Space Telescope (HST) is celebrating its 34th anniversary of the world's first space-based optical telescope, which paved the scientific pathway for NASA's James Webb Space…

Making magic happen: Engineering and designing theme parks

The themed entertainment industry is widespread and diverse, encompassing everything from theme parks to aquariums, zoos, water parks, museums and more. The Theme Park Engineering and Design…