'Spotlight' editor Walter V. Robinson to give Schatt Memorial Lecture at ASU

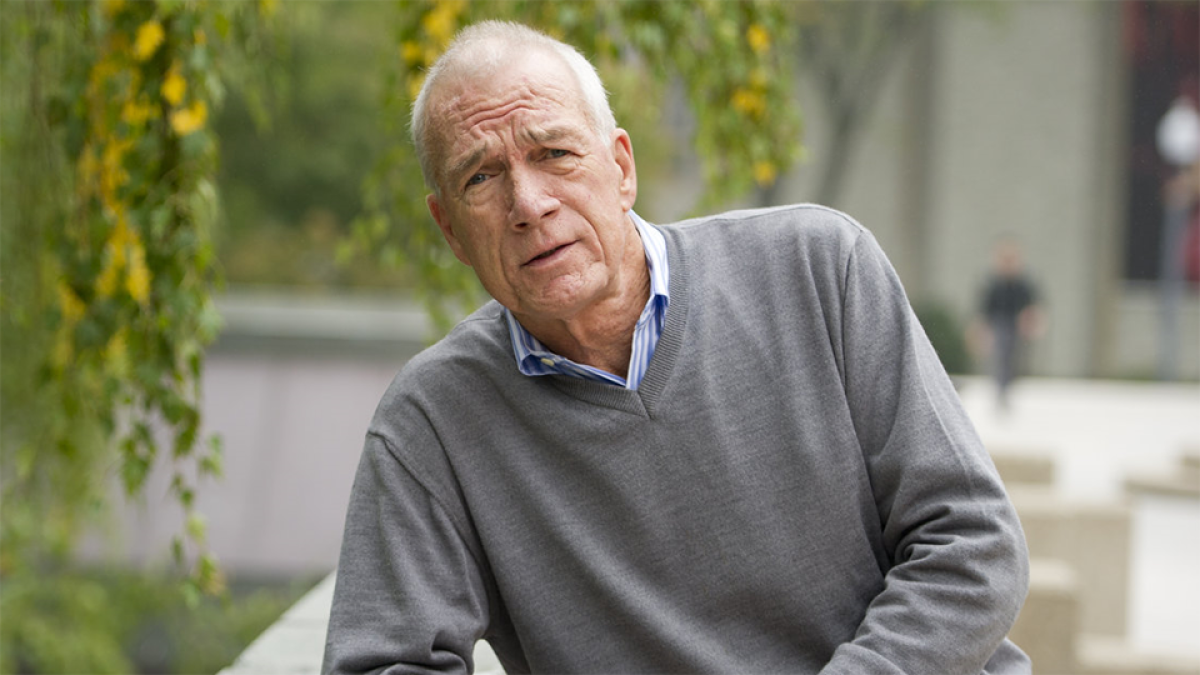

Walter V. Robinson, the longtime Boston Globe investigations editor who led the newspaper’s Pulitzer Prize-winning report on the Roman Catholic Church sexual abuse scandal, is the speaker at the annual Paul J. Schatt Memorial Lecture at the Cronkite School.

Walter V. Robinson, the Pulitzer Prize-winning editor who led the Boston Globe’s Spotlight investigation into the Roman Catholic Church, is the featured speaker of the 11th annual Paul J. Schatt Memorial Lecture at Arizona State University’s Walter Cronkite School of Journalism and Mass Communication.

Robinson, currently the Cronkite School’s Donald W. Reynolds Visiting Professor, will explore the past, present and future of investigative journalism during a public lecture at 7 p.m. Monday, Feb. 27, in the Cronkite School’s First Amendment Forum on ASU’s Downtown Phoenix campus.

Robinson serves as editor at large at the Boston Globe, where he has worked for 34 years. Previously, he led the Spotlight team, an investigative unit that won the 2003 Pulitzer Prize for Public Service for its comprehensive investigation into sexual abuse by Catholic priests.

Under Robinson’s leadership, the investigation brought to light a decades-long cover-up that included the crimes of nearly 250 priests. The probe was made into the film “Spotlight,” which won the 2015 Academy Awards for Best Picture and Original Screenplay.

“Walter Robinson embodies the very best in investigative journalism,” said Christopher Callahan, dean of the Cronkite School. “We have seen that first-hand this semester in the way he teaches and inspires our students, and we’re pleased that he’ll be sharing his insights and experiences with the entire school and the public at this event.”

As the Reynolds Visiting Professor at the Cronkite School, Robinson is teaching an investigative journalism class for graduate students and advanced undergraduates. He also works with reporters in Cronkite News, the student-staffed, professionally led news division of Arizona PBS.

Robinson began at the Globe in 1972, where he reported mainly on politics and government. He covered the White House during the Ronald Reagan and George H.W. Bush administrations and was the newspaper’s lead reporter for the 1988 and 1992 presidential elections.

Robinson was the roving foreign and national correspondent for the Globe in the late 1990s. Much of his reporting centered on artwork taken by the Nazis during World War II that ended up in American museums. For his work on the illicit trade of antiquities stolen from archeological sites, he received the first-ever Archaeological Institute of America Award for outstanding public service.

In 2007, Robinson became a distinguished professor of journalism at Northeastern University in Boston, and returned to the Globe as an editor-at-large in 2014.

The Cronkite School established the Schatt Lecture series in 2007 in honor of former Arizona Republic reporter, editor and columnist Paul J. Schatt. Schatt also taught public affairs reporting to Cronkite students for more than 30 years as an adjunct faculty member. The series in his name is supported by an annual gift from The Arizona Republic and an endowment created in Schatt’s memory by his widow, Laura Schatt-Thede.

Previous speakers have included Washington Post National Political Editor Steven Ginsberg, Pulitzer Prize-winning journalist and author Thomas E. Ricks, New York Times Deputy Editorial Page Editor Carla Robbins, CNN Senior Media Correspondent Brian Stelter and award-winning investigative journalist and author Mitchell Zuckoff.

More Law, journalism and politics

CBS News president to give keynote address at Cronkite School’s spring convocation

Ingrid Ciprián-Matthews, president of CBS News, will serve as the keynote speaker at Arizona State University’s Walter Cronkite…

School of Politics and Global Studies director's new book explores mass violence

Why do people commit atrocities and why are certain groups, including religious and ethnic, more vulnerable to large-scale…

ASU faculty contributing to improvement of Wikipedia

Many academics have a love-hate relationship with Wikipedia. While the website has information about almost anything you can…