Print in Polytechnic color

ASU print lab leads by example with an innovative approach — and it has the hardware to prove it

The death of the printing industry has been lamented by many a scribe in recent years, but a quick look at the efforts of Arizona State University’s Print and Imaging Lab leads one to believe that the reports of print’s demise have been greatly exaggerated.

The Print and Imaging Lab was born in 2005 when graphic information technology professor Thomas Schildgen saw a need for a change in the way that ASU was generating its printed materials.

“It all started with [ASU President] Michael Crow’s enterprise model,” Schildgen said. “That allowed us to give students experience while competing at a professional level with other companies in the industry.”

The enterprise model — in which classroom learning is augmented by entrepreneurship — would go on to make the state-of-the art Print and Imaging Lab self-sufficient over the next 10 years, requiring little to no funding from the university in order to operate.

Instead, the Print and Imaging Lab is the official print provider for ASU and bills the university for its services. It also handles requests for companies and individual consumers throughout the Arizona area. By being a 100 percent digital printing press, the lab is years ahead of where some traditional printing companies are today.

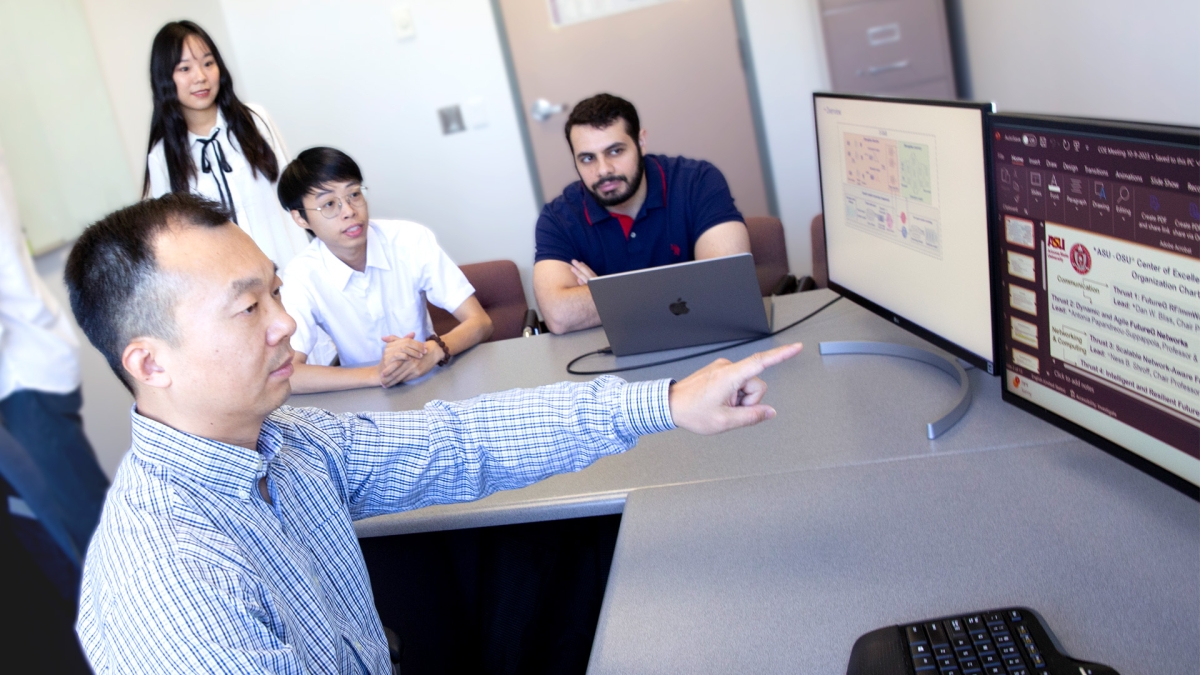

Josh Balcos (left) and Daniel Isaghoulian (right) trim a door wrap, as they talk with Cathy Skoglund and Chris Myers at the Print and Imaging Lab. on the Polytechnic campus.

Photo by Charlie Leight/ASU Now

Today, around 30 students learn and essentially receive on-the-job training at the lab, with many students working more than 20 paid hours a week. In fact, the students outnumber the three full-time employees at the lab; but it’s these faculty that keep the Print and Imaging Lab ahead of the industry curve — they are the key cogs in a finely tuned rotating series of parts.

The Polytechnic campus-based printers recently received a slew of awards. A dozen graphics awards came from the Western State Printing Alliance, a consortium of printing companies throughout Arizona, Colorado, Wyoming and New Mexico, while two staff members received employee achievement awards.

ASU alumnus Catherine Skoglund has been with the lab since 2006 as its director of operations and business development. Schildgen, her former professor, describes her as “the mastermind” behind the lab’s success. Skoglund can claim responsibility for procuring the equipment and implementing procedures at the lab that allow it to boast some of the faster turnaround times in the industry.

“Print is truly a cross-media industry, and we pride ourselves in that our students can deliver value at a company on day one,” Skoglund said. “Our students are just sought after on graduation — even before graduation.”

Skoglund was awarded with the Z.A. Prust Industry Achievement Award by the Western State Printing Alliance during the April awards ceremony. The award is named after former ASU professor Zeke Prust, who founded the university’s graphic communications in 1958, which could be considered the precursor to the modern-day lab.

“The Prust award is something I’ve always aspired to win, ever since I heard about Zeke Prust,” Skoglund said. “He was the professor to my professor (Schildgen), so it was just an exciting and amazing honor to be a recipient of the award.”

Chris Myers, the production manager at the lab, was awarded with the Employee Recognition Award by the Western State Printing Alliance and is responsible for managing the print processes for all incoming orders. He’s the one in the lab every day with the students as they work on deadline pressure to produce professional-quality materials.

That pressure creates a symbiotic relationship between the students that makes innovation a necessity, Myers said. The Sun Devil student workers are responsible for everything from information technology to comparing vendor quotes to developing new website templates for placing orders.

The amount of work the students handle at the lab is not to be underestimated. The Large Format department, which handles prints for oversize materials like wallpapers and door banners, was created based on a research project done by one of the lab’s former students.

“For me, there’s no way I could do it all, so I rely heavily on [the students] to get it done,” Myers said. “So I think that’s part of the learning curve too, is that I can’t do it all, so they have to step up and do their part. And I think as each person does their part, we’re successful as a team, and I think that’s the most important part.”

“Chris and Cathy have provided an amazing amount of, one: knowledge from the industry in training us,” said graduating senior Chris Halkovic, who manages the online print ordering system for the entire university. “I mean, when we go out there, we know that we’re going to get a job.”

The Print and Imaging Lab has no plans on remaining stagnant, a frequent flaw noted when looking at the shortcoming of the print industry. Skoglund travels to conferences and networks with companies to stay abreast of the latest and greatest print technologies. Top industry leaders, like Xerox and Hewlett-Packard, often provide equipment to the lab at discounted rates as a way of investing in the future of their own companies.

“Not only do they want to provide this service to their customers, the print companies, they also want it for themselves,” Skoglund said. “Xerox wants our students to funnel and work for Xerox, and HP the same. They’re really investing into outreach and education, now that the economy is bouncing back.”

“The industry needs the youth coming in there and reviving their printing operations with vision,” Myers said. “There’s just something about print that’s in our DNA. … I tease some of my older friends, ‘Printing is sexy again.’”

More Science and technology

Advanced packaging the next big thing in semiconductors — and no, we're not talking about boxes

Microchips are hot. The tiny bits of silicon are integral to 21st-century life because they power the smartphones we rely on, the cars we drive and the advanced weaponry that is the backbone of…

Securing the wireless spectrum

The number of devices using wireless communications networks for telephone calls, texting, data and more has grown from 336 million in 2013 to 523 million in 2022, according to data from U.S.…

New interactive game educates children on heat safety

Ask A Biologist, a long-running K–12 educational outreach effort by the School of Life Sciences at Arizona State University, has launched its latest interactive educational game, called "Beat the…