Designs on student success

ASU Print and Imaging Lab garners kudos both for its high-quality products and its top-performing student staff

There’s a lab on Arizona State University’s Polytechnic campus where students are hard at work, gaining knowledge and producing results.

Only there are no test tubes or microscopes in this space. Rather, the 6,500-square-foot facility on the Polytechnic campus is a bustling mix of state-of-the art digital printers and vintage letterpressLetterpress — a form of relief printing that uses pressure and a raised surface to create something embossed — is an old technique, but the Print Lab is using the equipment in a new way. Print Lab Director Cathy Skoglund suggested using it to do die cut products and now, many specialty items, such as cut-out Sparky masks on a stick, are made that way machines.

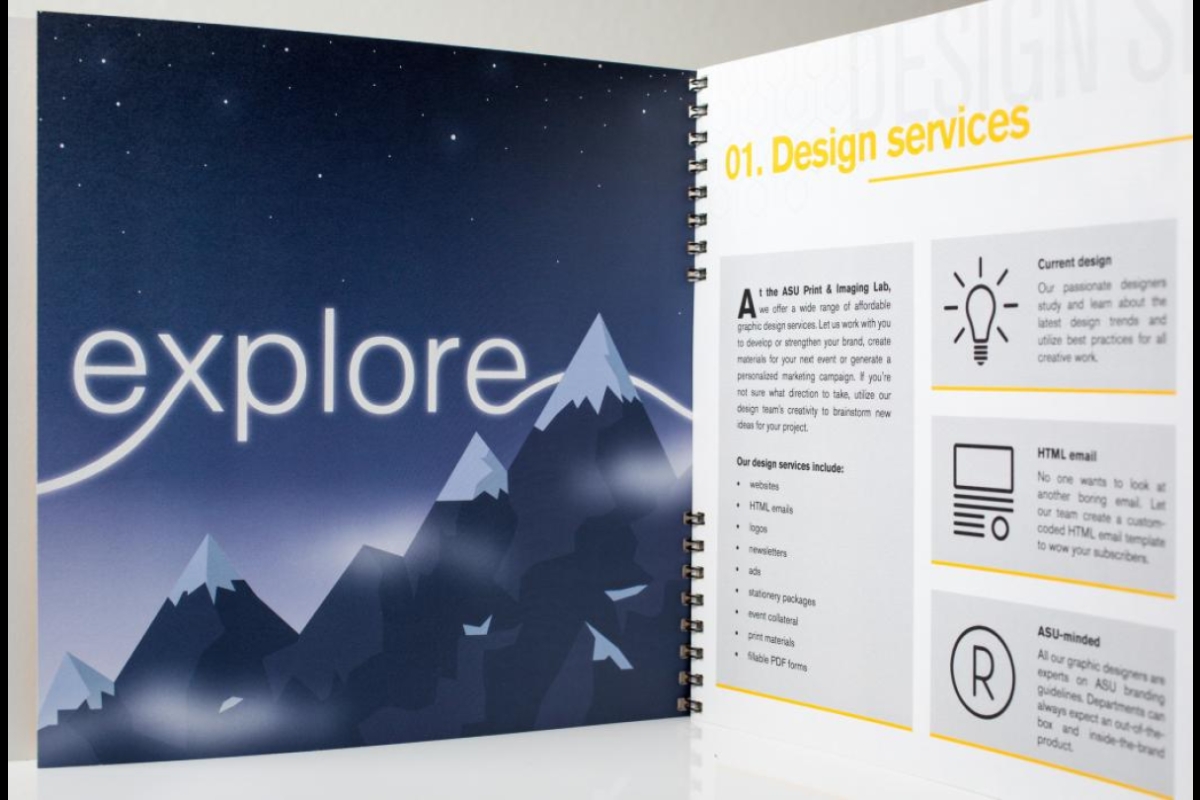

This is the ASU Print and Imaging Lab, where the results come in the form of award-winning printed materials.

Those program posters all over campus? A professor’s business cards? Three-story-tall signage on ASU buildings? All come from the unit known as the Print Lab.

And it’s more than just the materials it produces. The Print Lab puts an emphasis on the lab part, keeping the students’ growth as the focus.

Cathy Skoglund, director at the Print Lab, said education is a top priority. The ASU alum is one of two non-student staffers; nearly 30 students make up the bulk of the crew. That’s about a 60 percent increase over the previous year.

“At first I had to beg students to come work here, and now we have a waiting list,” said Skoglund, adding that the lab’s popularity is due in large part to word of mouth.

“It is now the place to work. All the students who work in the Print Lab get two or three years of experience under their belt before graduation.”

Don’t let the student-in-training part fool you.

“It isn’t a lab that just creates student work; it creates communication materials for the university, and we have very high standards as to what we produce,” said Ross Greenblat, a 2010 Graphic Information Technology (GIT) graduate who now works for Chicago-based marketing and advertising firm Leo Burnett on such campaigns as the McDonald’s 2015 Super Bowl spot.

“If something is a little bit off [at the Print Lab], then it is reprinted and not shipped to the client unless we think it is correct.”

These are top-quality materials being produced, and it’s getting noticed.

This fall, the Print Lab won one of the most elite honors in printing, honored with a Benny (Best of Category) at the national Premier Print Awards Competition, as well as a certificate of merit and five awards of recognition. The awards, given by the Printing Industries of America, pitched the students’ work in competition against that of professional printing companies.

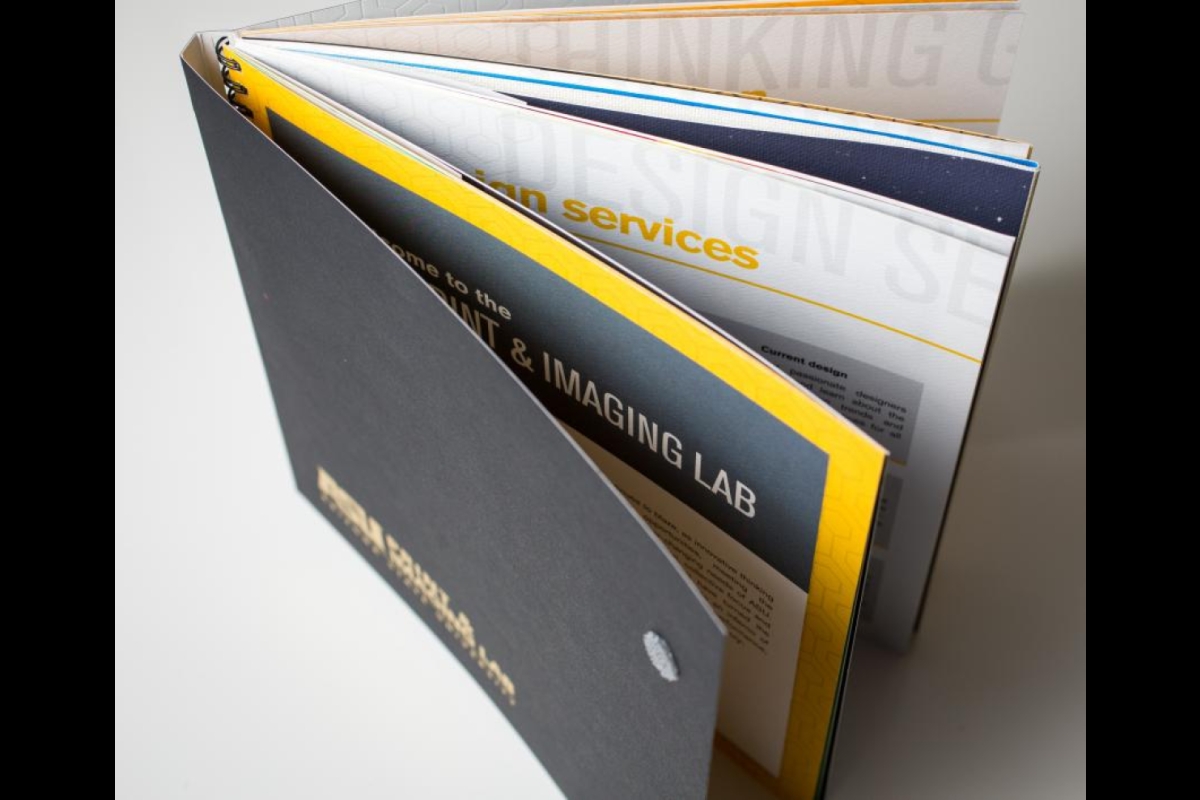

The Benny was for a special booklet that used 14 different stocks, showcasing what the Print Lab can do. Assembly required gloves to prevent oil marks, the books were blown with an air compressor to get all the paper flakes out, and each was hand-checked.

That level of detail clearly made an impression. The award is a very big deal, Skoglund said, and further proof of what the crew there is accomplishing.

Many majors, many skills

The Print Lab is a self-funding unit of the GIT program in the Polytechnic School, part of the Ira A. Fulton Schools of Engineering. And though many of the students who work there are GIT majors, there are also software engineers, mechanical engineering, human resources and business majors.

The jobs they perform are likewise wide-ranging, from project managers who provide customer service and estimates to graphic designers and press operators.

Daniel Isaghoulian, a sophomore studying human resources in the W. P. Carey School of Business, works in the large-format side of the Print Lab doing more of the business side and customer service.

“You get experience doing a multitude of stuff while you work here,” he said. “… Everything is applied here. There is no small scope of what we do; we do everything.”

One of his favorite experiences was putting up a large sunburst installation on the side of the Biodesign Institute on the Tempe campus (it required the use of a boom lift, a highlight for the business major), but it’s not only the big dramatic things that will stay with him. Learning to train employees and keep inventory stocked will translate to many careers after graduation.

Kyle Pendley stumbled upon the Print Lab quite unexpectedly. A former elementary teacher of his who was then working on the Polytechnic campus gave Pendley a tour to try to get him interested in college. The tour included the Print Lab.

“When I saw what all the students were doing, it blew me away,” Pendley said. It’s not just a class with lectures, he said, but real accounts in which students are interacting with real clients.

Now, the senior GIT major is a print media specialist, helping students learn the new machinery. He’s one of two full-time student employees on staff.

After his freshman year, Skoglund sent him to Boston to become HP Indigo-certified. The Indigo is one of the industry front-runners in digital presses. Part of Pendley’s training included taking the machine apart and learning all the components.

“It’s not just graphics. It’s also engineering mixed with lots of left- and right-brain thinking,” Pendley said. “And I like solving problems, so that’s where I need to be. … The industry is shifting; people can’t just be a graphic artist anymore. They have to know all the aspects of a project.”

That real-world industry focus is a key part of the Print Lab.

Every month or so, the students tour a local facility to meet vendors and network. Most of the students are hunted down by companies, Pendley said, and it’s common to have a job lined up come graduation week, if not before.

“The Print Lab is what has given me the confidence … to feel valuable, to hone my skills,” said Pendley, whose brother Cody also works in the lab.

Out in the work world

One of the jobs at the Print Lab is within the bindery department. This position includes such finishing actions as folding, scoring and die cutting. Many of the students, including the graphic artists, begin their careers in this department.

“You need to know how to finish a job before you learn how to design it,” said Skoglund, who pointed out that students are better prepared for industry if they work all aspects.

Jake Walker, CEO of design and marketing company CP Graphics in Tucson, said the ASU’s Print Lab is unique among universities in its focus on new technologies and the changing direction of the industry.

“The experience is the most important deciding factor when I am evaluating candidates,” Walker said. “The degree is a check box for me; it's a requirement. Your experience shows me your drive, work ethic and desire to make a difference in a real-world environment.”

ASU alumni (from left) Haris Heldic, Ashley Yost and Damon Tennyson proudly represent Sun Devil pride in the midst of Wildcat territory. All three came out of the ASU Print Lab and were recruited to work at design and marketing firm CP Graphics in Tucson. Photo courtesy Haris Heldic.

Walker first came across the Print Lab’s students at Dscoop, an annual conference of HP Indigo users. Skoglund and Chris Myers, Print Lab manager of print and design, introduced him to GIT major Haris Heldic. After seeing Heldic’s drive and experience, Walker told him there would be a job waiting for him after graduation.

Heldic, who graduated in 2013 and now is operations manager at CP Graphics, was but the first of a handful of Print Lab alums hired at the Tucson firm (“It's always nice to have some backup going up against the Wildcats,” Heldic said).

He praises the experience he gained at ASU, from production on up into management. He even got a taste of real-world deadlines.

“My favorite memory would have to be pulling off the crazy last-minute jobs,” Heldic said. “I had a client call me at 4:45 one late afternoon and literally within 15 minutes, I had the job pushed through prepress, printed on the Indigo, cut in production and shipped out for delivery in the morning.”

Walker has been so impressed with what has come out of the Print Lab that he wrote a letter to ASU President Michael M. Crow praising the lab’s preparation of students.

“I think it's important that educators who are willing to take an innovative approach are recognized and encouraged to continue to take those risks,” said Walker, who pointed out his praise isn’t a form of nepotism; he attended the University of Kansas.

“I also felt it was very important to recognize Cathy Skoglund for the impact she is having on such a large industry.”

In a world of electronic screens and digital information, there’s still a place for physical printed products.

“Everyone is saying printing is gone; that isn’t the case at all,” Skoglund said. “The unnecessary printing is gone — what it’s evolved to has become so much more scientific and direct.”

Video by Ken Fagan/ASU Now

More Science and technology

Advanced packaging the next big thing in semiconductors — and no, we're not talking about boxes

Microchips are hot. The tiny bits of silicon are integral to 21st-century life because they power the smartphones we rely on, the cars we drive and the advanced weaponry that is the backbone of…

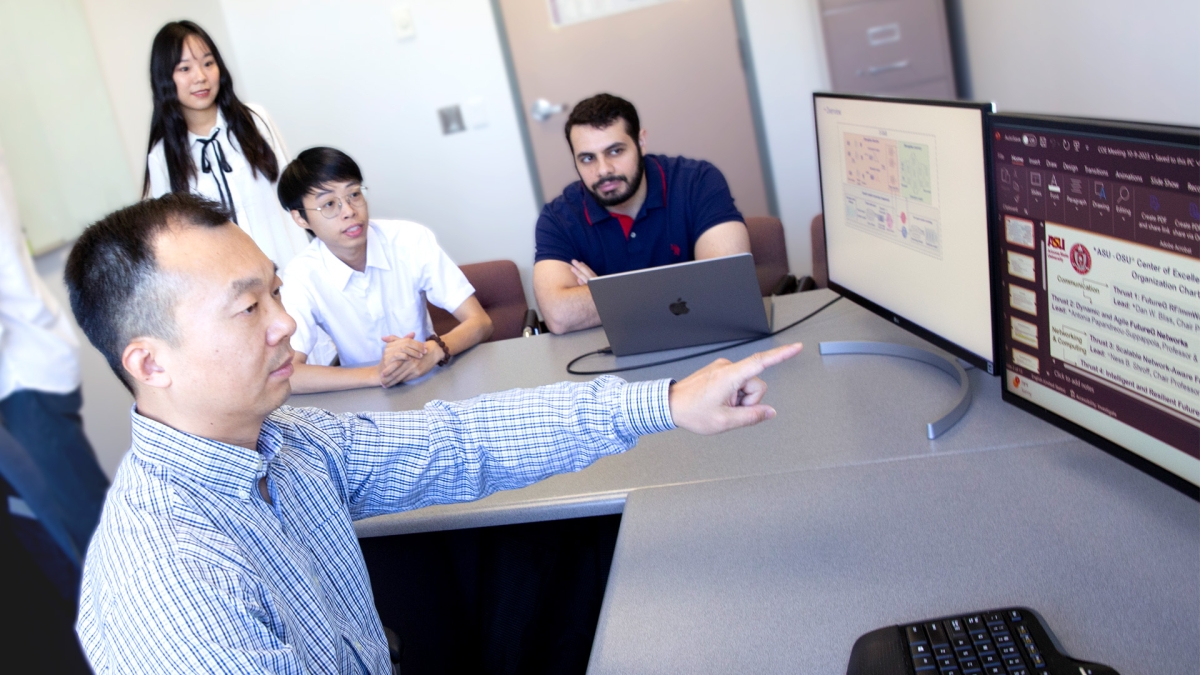

Securing the wireless spectrum

The number of devices using wireless communications networks for telephone calls, texting, data and more has grown from 336 million in 2013 to 523 million in 2022, according to data from U.S.…

New interactive game educates children on heat safety

Ask A Biologist, a long-running K–12 educational outreach effort by the School of Life Sciences at Arizona State University, has launched its latest interactive educational game, called "Beat the…